Home / Industries / Tools and Equipment

Tools & Equipment Parts Manufacturing

Manufacture of housings for household tools and industrial equipment

- Perfect interpretation of component functionality

- Parts fit together nicely

FirstMold's Mastery in Tools & Equipment Fabrication

Experiences in Tools & Equipment:

Specializing in both household and industrial tools, along with a broad spectrum of equipment housings, we champion the art of creating exceptional products. Our portfolio showcases our versatility and precision across key processes:

- Injection Molding for ergonomic handles and durable tool casings, ensuring comfort and longevity.

- CNC Machining to produce intricate metal components for machinery and precision instruments, offering unparalleled accuracy.

- 3D Printing for rapid prototyping of innovative tool designs and complex equipment parts, accelerating development timelines.

- Die Casting for robust and lightweight aluminum housings, ideal for high-performance and portable equipment.

Tools & Equipment Parts Gallery

Household Tools

Items like screwdrivers, pliers, and gardening tools

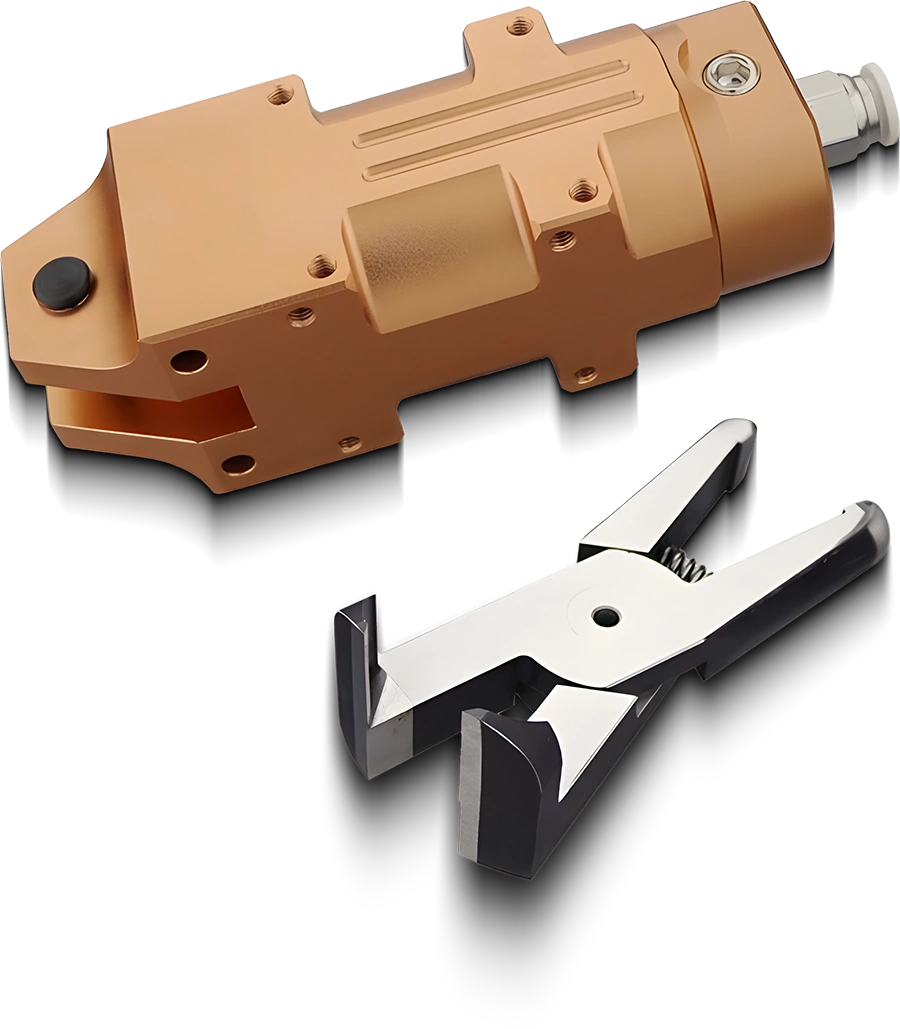

Industrial Tools

High precision instruments and machinery components

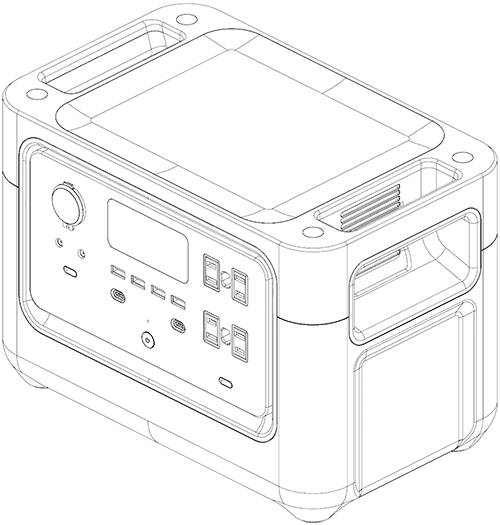

Industry Equipment Housing

Protective casings for machinery and electronics

Innovative Design Housing

Custom housings for new industry equipment

Tools and Equipment for Daily Life

Bike computer mount handleset part

| Process: | Mold Making, Injection Molding |

| Materials: | PC |

| Solutions: | Mass Production |

| Tolerance: | ±0.005" |

Tool scale housings

| Process: | Production Tooling, Injection Molding |

| Materials: | ABS+HIPS |

| Solutions: | Mass Production |

| Tolerance: | ±0.005" |

Tools and Equipment for Industry

Industrial equipment bases

| Process: | CNC Machining |

| Materials: | Steel |

| Solutions: | Mass Production |

| Tolerance: | ±0.002" |

Industrial mold inserts

| Process: | CNC Machining |

| Materials: | Steel |

| Solutions: | Low-Volume Production |

| Tolerance: | ±0.002" |

Reviews from Tools & Equipment Clients

“Fresh and innovation in garden tool design represents us in the market and the search for an appropriate manufacturing partner who guarantees bringing our complex designs to life is a challenge. Then came the decisive moment – until we cooperated with FirstMold. Unlike other manufacturers, their specialization in injection molding allowed us to get ergonomic handles for our collection of trowels and spades, and ones that are not only durable – but made, ostensibly, beautiful as well, as well. My working partner, Charles Jyo of FirstMold, not only went the extra mile in providing exceptional services to me, but also the helpful insight she shared were directly of great value to me. This is our favorite part, watching the customers enjoy the product and working to improve it!”

Marcus Tan

Chief Engineer

“I appreciate and look forward to cooperating with FirstMold for the production of precision parts that have been essential for our site construction equipment. The plastic parts were produce by them with injection molding and these parts played a key role in increasing the durability of our power drills. Among the qualities exhibited by FirstMold is the consistency in quality and their reliability to meeting delivery deadlines that have made them a preferred supplier in the production of our product.“

Ethan Wright

Project Manager

“The FirstMold’s manufacturing, mostly precision machining technology, is required for the prototyping of highly detailed metal components for our final products. These have to meet the highest manufacturing and reliability standards. Being able to recognize and address the precision needs of the industry and devoting a great deal of efforts to the creation of the devices that meet those requirements completely is such a priceless advantage we benefit from when they are involved into our business.”

Amanda Lee

Director of Product Development

Surface Treatment For Tools & Equipment Parts

Metal Solution

- Powder Coating

- Anodizing

- Electroplating

- Laser Engraving

- Thermal Spraying

Plastic Solution

- Silk Screening

- Painting

- Pad Printing

- Hot Stamping

- UV Coating