カスタム自動車部品製造ソリューション

自動車部品製造の専門工場で、真にオンデマンド生産を実現。

- Superior product performance with tolerance up to ±0.127mm(±0.005″)

- 社内生産能力

- 認証IATF16949、ISO9001

Setting New Standards for the Automotive Parts Manufacturing Industry

自動車業界での経験:

Automotive components manufacturing represents the largest share of FirstMold’s business across all industries over the past decade. We recognize the need for newer improved standards of performance, safety and efficiency in the automotive industry. This is why we continue to explore how our custom manufacturing solutions can help arrest the challenges of making vehicles and mobility components alike.

Automotive Parts Manufacturing List

Our automotive components manufacturing means mainly include:

We have manufactured a wide range of automotive parts, including interior components, exterior components, car lights, etc. Among all the industries we serve, injection molding and mold-making services account for the largest share of annual revenue in the automotive sector, while CNC machining and 3D printing also hold a significant proportion within the industry.

注釈 ほとんどのプロジェクトでクライアントと守秘義務契約を結んでいるため、クライアントとのコミュニケーションを通じて同意を得た上で、自動車業界のいくつかの製品だけを選んで外観を展示することができる。

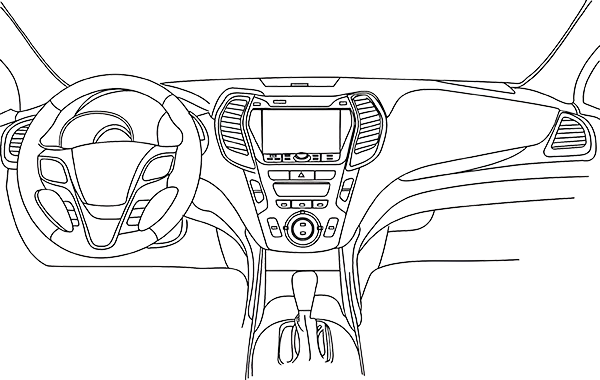

内装部品製造

エアバッグ

| プロセス | 金型製作、射出成形 |

| 素材: | TP、SI |

| 仕上げ: | 金型研磨 |

| 寛容だ: | ±0.005" |

サンルーフレールカバー

| プロセス | 金型製作、射出成形 |

| 素材: | TP、SI |

| 仕上げ: | 金型研磨 |

| 寛容だ: | ±0.005" |

室内ドアハンドル

| プロセス | 金型製作、射出成形 |

| 素材: | TP、SI |

| 仕上げ: | 金型研磨 |

| 寛容だ: | ±0.005" |

アンビエントライトブラケット

| プロセス | 金型製作、射出成形 |

| 素材: | TP、SI |

| 仕上げ: | 金型研磨 |

| 寛容だ: | ±0.005" |

外装部品製造

エクステリア・ドアハンドル

| プロセス | 金型製作、射出成形 |

| 素材: | TP、SI |

| 仕上げ: | 金型研磨 |

| 寛容だ: | ±0.005" |

ヘッドライト

| プロセス | 金型製作、射出成形 |

| 素材: | TP、SI |

| 仕上げ: | 金型研磨 |

| 寛容だ: | ±0.005" |

テールライトカバー

| プロセス | 金型製作、射出成形 |

| 素材: | TP、SI |

| 仕上げ: | 金型研磨 |

| 寛容だ: | ±0.005" |

リアフォグランプリフレクター

| プロセス | 金型製作、射出成形 |

| 素材: | TP、SI |

| 仕上げ: | 金型研磨 |

| 寛容だ: | ±0.005" |

自動車部品製造ソリューション

After years of dedication to vehicle parts manufacturing and serving hundreds of auto parts projects, we have developed several sets of solutions for you to choose from. Generally, they employ distinct manufacturing processes. While some processes may appear similar, their workflows, philosophies, purposes, and every detail vary. Below are some of the automotive parts manufacturing solutions we recommend:

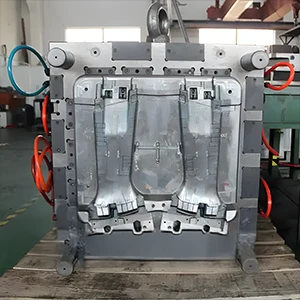

自動車用射出成形金型と射出成形

Suitable for aftermarket suppliers, Tier 1 and Tier 2 suppliers, and specialty auto firms requiring high-quality, precise, and durable plastic parts in large volumes

- 大規模生産における効率性

- 均一性と高精度

- 多様な素材適合性

- 合理化された組立工程

- カスタマイズ可能な仕上げ

自動車プロトタイピング

デザイン会社、OEMの研究開発部門、アフターマーケット部品会社、自動車分野のイノベーションとカスタムソリューションに注力する新興企業に最適です。

- 複雑なデザインの実現

- 重量と強度の最適化

- カスタマイズ可能な美学

- 妥協なき複雑さ

- 費用対効果の高い少量生産

世界中の様々な有名自動車ブランドから信頼されています。

- 相手先ブランド製造業者(OEM)

- アフターマーケットパーツサプライヤー

- 自動車用ティア1およびティア2サプライヤー

- 電気自動車(EV)メーカー:

- 自動車設計・エンジニアリング会社

- 特殊車輌およびカスタム車輌メーカー

私たちと仕事をする理由

高い寸法精度と公差

We can machine vehicle parts with tolerances as tight as ±0.001", delivering up to 10 times the precision and tolerances that other service providers avail you.

DFM分析

We offer hands-on DFM analysis, helping our clients explore potential causes of failures, design inconsistencies, avenues for cost efficiency, improved safety and performance optimization in auto component design for better results.

優れた透明性のある品質管理

当社のQCプロセスは厳格かつ一貫しています。我々は、IATF 16949 2016、ISO 9001:2015のような関連する認証を持っており、我々は適合証明書、材料証明書と高度な検査報告書をクライアントに提供します。

サプライチェーンの敏捷性

当社のオンデマンド・ソリューションと少量生産サービスは、緊急のダウンタイム、ジャスト・イン・タイムの供給、タイトなスケジュールでの部品回収・交換に対応するのに適しています。

仕上げとマスカスタマイゼーション

純正の高級自動車パーツの外観、フィーリング、性能を向上させるために、高い化粧性と機能性を備えたさまざまな仕上げからお選びいただけます。また、カスタムオーダーや特別仕様車に合わせたカスタマイズパーツも製造しています。

市場優位性を得るためのリードタイム短縮

納期が厳しい?競合他社に勝ちたいですか?当社の社内生産能力と専門家チームが、サイクルタイムを最大50%短縮するお手伝いをいたします。

自動車業界のクライアントからのレビュー

Regarding our automotive industry clients, there’s always been one aspect we take particular pride in. Many of the auto industry clients who partnered with us at the company’s inception still maintain a close collaborative relationship with us to this day.

When we first started working with First Mold on the new car seat adjustment parts project, we were initially quite concerned. However, once they received the order, their professionalism in mold manufacturing quickly became apparent. They carefully improved the design for the complex undercut areas, avoiding the problem of difficult mold release. During injection molding, they were precise in material control, producing parts with excellent surface quality and strength. Although there were minor equipment issues, they fixed them quickly without affecting the timeline. A small number of metal connectors were CNC-machined with high precision, fitting perfectly, and the delivery was on time, making the vehicle assembly smooth. We would definitely work with them again.

Previously, we entrusted First Mold with the production of a car dashboard shell, which had a complex design and high demands on appearance and precision. They optimized the mold structure through simulation analysis to prevent cooling defects. The on-site processing was meticulous, with fine polishing. During injection molding, they repeatedly adjusted parameters and tested materials to meet standards for light resistance and texture, overcoming issues like color variation and brittleness. The CNC-machined metal frame was exquisite, and although the timeline was slightly delayed due to logistics issues, they actively coordinated and the final result exceeded our expectations. They are very reliable.

For the development of a new car model’s headlamp cover, we chose First Mold. In the mold, they reinforced thin-walled areas to prevent damage. They used special optical plastic for the injection molding, overcoming difficulties with forming and ensuring the transparency was up to standard, so the light refraction was correct. The metal clips that accompanied the part were precisely CNC-machined, and assembly went smoothly. Although there were delays in material supply, they proactively found alternatives and rechecked quality, delivering on time. The product greatly enhanced the headlamp's performance, and we were satisfied with the cooperation.

We handed over our car wiper bracket production project to First Mold, and at first, we had some doubts about manufacturing the bracket, which had complex curves and high strength requirements. In the injection molding process, they carefully selected durable, weather-resistant materials to address issues like rapid material aging and brittleness, producing a bracket with excellent toughness. There was a brief equipment glitch, but their maintenance team responded quickly and fixed the problem. The accompanying metal connecting shaft was CNC-machined with high precision, ensuring a perfect fit. The final delivery was on time, helping us launch our product as scheduled. We found them very reliable.

The design had to be aesthetically pleasing and in line with our brand style, while also being impact-resistant and corrosion-resistant. In the injection molding process, they experimented with several eco-friendly material combinations, successfully balancing both appearance and performance. The resulting hub covers had a long-lasting, bright color and were tough in texture. The CNC-machined metal clips were finely crafted and ensured secure installation. During the project, there were some delays in material supply due to environmental inspections, but First Mold actively found compliant sources and adjusted the production schedule. Although the delivery was slightly delayed, the product quality was excellent, and we will definitely continue working with them in the future.

クリックひとつで完璧なクラフト

Material Options for Auto Applications

FirstMoldでは、自動車業界の厳しい基準に準拠した材料を優先的に調達し、各コンポーネントが最高の品質と安全基準を満たすようにしています。また、お客様指定のサプライヤーからの調達も可能で、柔軟性を提供し、材料がプロジェクトの仕様と完全に一致することを保証します。使用されるすべての材料について、詳細な材料レポートを提供し、透明性と品質へのコミットメントを確認します。

私たちの包括的な品質管理システムは、有害な排出物のチェックを含む厳格な安全基準を満たすことを保証するために、材料を厳格にテストします。高度な材料試験機を用いて、すべての部品に人体に悪影響を及ぼす物質が含まれていないことを確認し、安全で信頼性が高く、業界に準拠した自動車部品を生産することに専念しています。

お問い合わせ

フォームにご記入の上、24時間以内に返信いたします。