Home / PA Injection Molding

PA Injection Molding

For products demanding high mechanical strength, look no further than PA injection molding (Polyamide)

- PA6, PA66, glass-filled, and mineral-filled material options

- The combination with glass fibers to significantly strengthen the properties

- Precisely controlling the drying level of PA/Polyamide

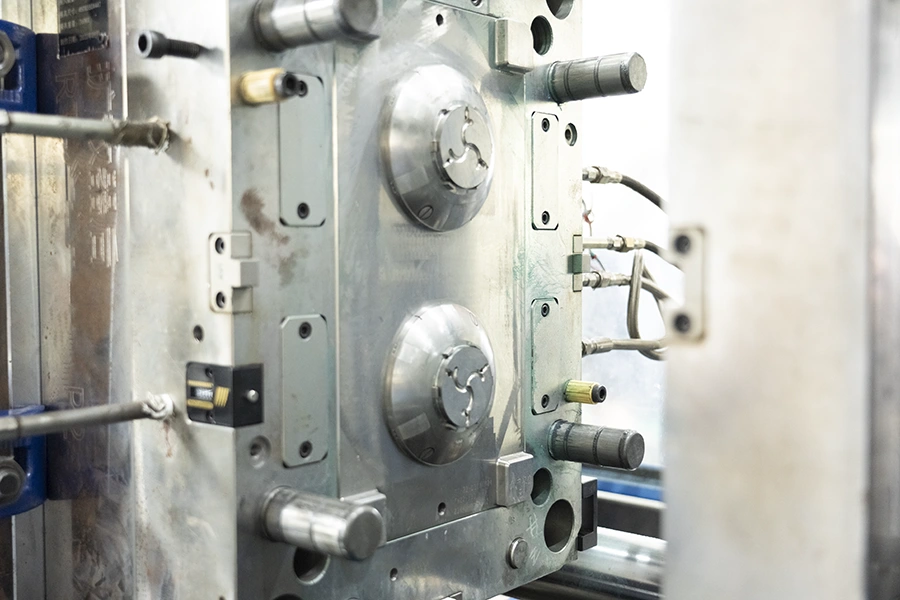

First Mold Is A Trusted Supplier Proficient in PA Injection Molding

Given the volume of projects we undertake in the automotive industry, we frequently encounter product demands utilizing PA materials.

Over ten years of mold design and injection molding experience have equipped us to overcome all defects commonly encountered in PA injection molding.

Specializing in the application of PA6+GF and PA66+GF materials, combined with high-precision injection molding machines and meticulous production management, First Mold offer various cooperation models to suit your needs with FirstMold.

Applications of Our PA Injection Molding Services

Due to PA materials’ mechanical properties, excellent toughness, and impact resistance, they are widely used in the automotive industry.

Consumer Electronics

- Smartphone Casings

- Tablet Frames

- Laptop Housings

- Keyboard Keys

- Camera Drones

- Wearable Devices

- Speaker Components

Aerospace

- Cable ties and clamps

- Bushings and bearings

- Interior cabin components

- Structural brackets

- Door handles and latches

- Protective covers

- Lighting fixtures and housings

Tools & Equipment

- Housing for Power Tools

- Lawn and Garden Tool Components

- Toolbox Latches and Hinges

- Hydraulic Lines Connectors

- Guide Rails and Slides

- Filtration Components

Electrical

- Circuit Breaker Components

- Switchgear Components

- Terminal Blocks

- Bobbin and Coil Formers

- Electric Motor Components

- Sensor Housings

- Solar Panel Components

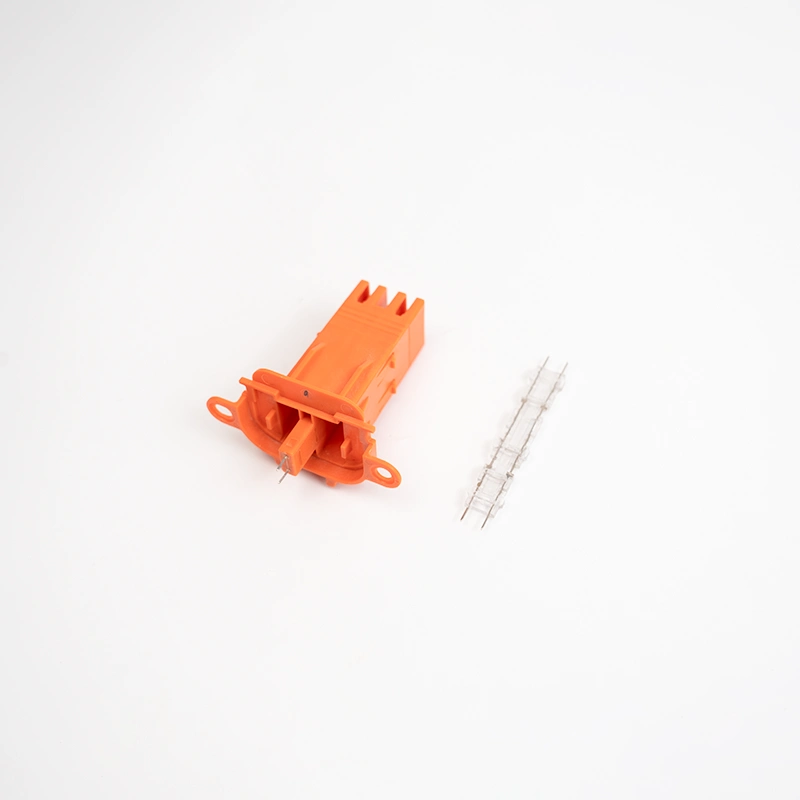

Here are some case study images of Nylon-material parts injection molded by FirstMold:

PP

PE

PC

PVC

ABS

PA

POM

PBT

PMMA

PEEK

PA Injection Molding Quality Assurance

- Regular maintenance and inspection of molds

- monitoring the process with real-time data collection and analysis

- Adhering to relevant industry standards and certifications

- skilled workforce of executing complex projects

Material Source Assurance

FirstMold has built a decade-long partnership with reliable material suppliers. We provide material certifications and are also flexible to source materials from suppliers you recommend.

Testing Assurance

With multiple Coordinate Measuring Machines (CMM), material testing instruments, quadratic element vision measure, and environmental testing devices at our disposal, we ensure that every injection molded part meets our stringent quality criteria.

Mold Design Assurance

Our mold design and production teams work in close collaboration. Through multiple professional team meetings, we finalize the mold design plans, no rish at all.

PA Injection Molding Cases

Learn a case study of how an injection molding plant manufactures high-quality lint remover parts through precision injection molding.

A simple case of mass production of automotive PCB headers with various insert injection molding applications in the automotive industry.

Explore our case study on scooter wheel hub production using advanced insert molding. Discover how we achieve superior precision.

Discover how FirstMold's mold making & injection molding techniques addressed intricate design challenges in producing high-quality multi-functional hair dryer.