Home / POM Injection Molding

POM Injection Molding

Ultimate plastic solution that comes closest to metal (Polyformaldehyde / Delrin).

- Manufacturing of plastic parts with superior lubricity and fatigue resistance

- Capability for high-quality production in both large and small batches

- Multi-tiered product quality assurance

Industry Experts In POM Injection Molding

At FirstMold, our understanding of POM plastics far exceeds that of our rivals. We excel in working with a broad array of Delrin’s modified materials, including but not limited to, enhanced toughness, wear resistance, and UV protection POM variants.

Our meticulous approach and advanced knowledge position us at the forefront, ensuring exceptional quality and precision in POM injection molding projects. Choose FirstMold, where excellence is not just achieved but guaranteed.

Applications of Acetal Injection Molding

POM is widely used in industrial manufacturing due to its metal-like properties, self-lubrication, fatigue resistance, thermal stability, and wear resistance, serving a multitude of industries.

Automotive & EV

- Door lock mechanisms

- Window lift gears and sliders

- Seat belt components and buckles

- Engine cover parts

- Power steering components

- Suspension bushings

- Lighting fixtures

Machinery Manufacturing

- Gears and sprockets

- Conveyor system components

- Valve bodies and components

- Rollers and wheels

- Couplings and connectors

- Precision screws and nuts

- Sliding and guiding elements

Electrical and Electronics

- Switch components

- Coil bobbins

- Light sockets and holders

- Relay cases

- Cable clips and ties

- Wire harness components

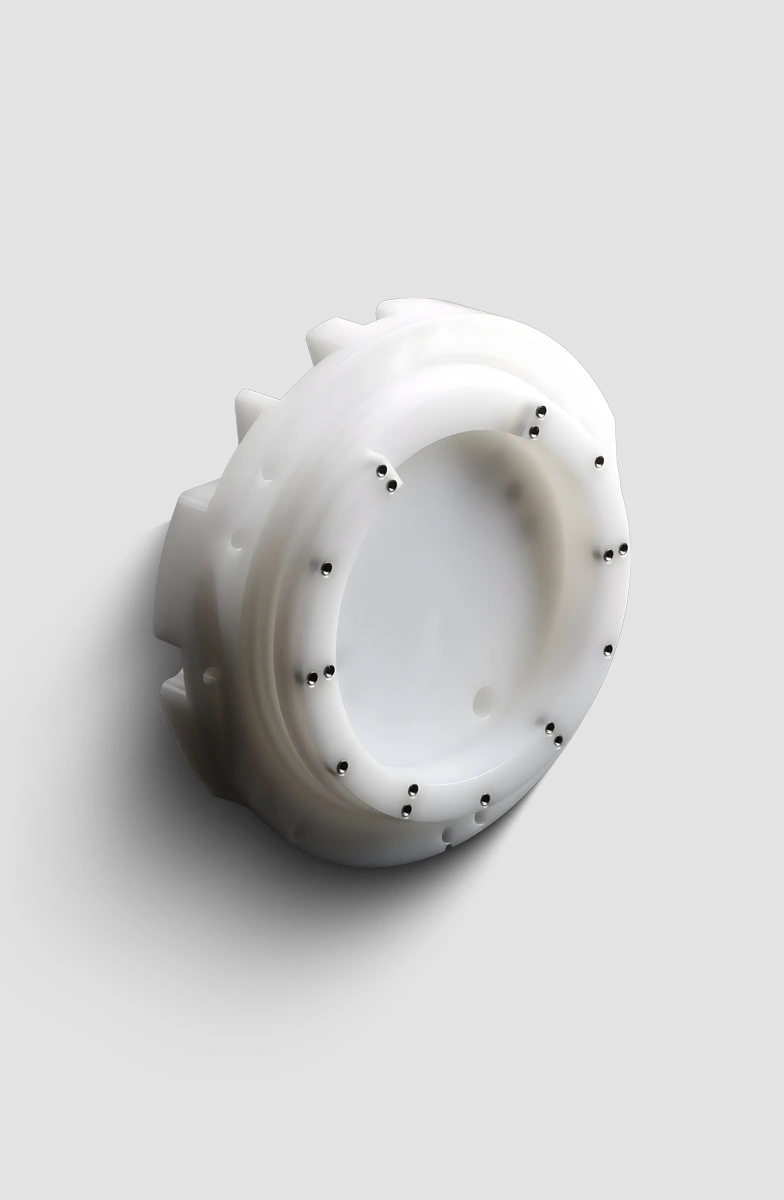

Precision Instrument

- Optical lens mounts and housings

- Analytical instrument components

- Surgical instruments and components

- Sealing rings and washers

- Calibration equipment components

- Fluid handling components

- Camera gears & housings

PP

PE

PC

PVC

ABS

PA

POM

PBT

PMMA

PEEK

POM Plastic Injection Molding Capabilities

Our exceptional POM injection molding capabilities are not just talk; they are demonstrated in the following areas:

Material Expertise:

Equipment:

Mold Design

Design Support:

Problem-Solving:

Supply Chain Management:

Quality Assurance

Advanced testing equipment and scientific product inspection protocols have propelled us to become industry leaders in the POM injection molding field.

Scalable Production

For small quantities, we offer prototype mold solutions or can utilize CNC prototyping for POM material products. For large quantities, we are capable of mass injection molding. No minimum order quantity requirement.

Post-Processing Services

We have post-processing techniques such as silk screening, etching, laser engraving, and spraying. Additionally, we have professional partners specializing in electroplating and anodizing, with whom we have cooperated for over ten years.

PP Injection Molding Cases

FirstMold's custom hair trimmer manufacturing meets stringent customer requirements for appearance and performance. This is a case.