Home / PEEK Injection Molding

PEEK Injection Molding

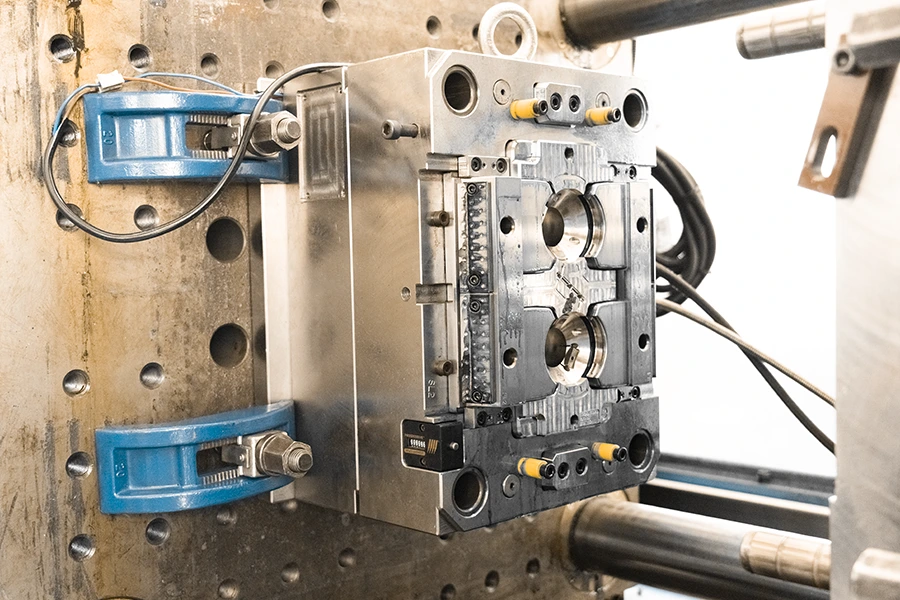

As an ultra-high-performance specialty engineering plastic, PEEK plastic has perfect physical and chemical properties. PEEK has become a core material in fields such as aviation and semiconductor industries. Through precision injection molding technology, PEEK can meet stringent demands ranging from minimally invasive surgical instruments (<0.1mm wall thickness) to deep-well exploration seals (150MPa pressure).

Why Choose PEEK Injection Molding

PEEK injection-molded parts demonstrate remarkable performance in extreme environments compared to common plastics like PP, ABS, and nylon. While ordinary plastics cannot withstand high temperatures and are prone to deformation and corrosion, PEEK maintains stable operation at 260°C. Additionally, PEEK injection-molded products feature high strength and resistance to strong acids. This is why PEEK plastic is ideal for manufacturing precision wear-resistant components such as aerospace engine parts and medical implants.

- High-Temperature Resistance: Continuous service at 260°C, short-term tolerance up to 300°C.

- Mechanical Strength: Tensile strength 90-100 MPa, 4 times the wear resistance of PTFE

- Chemical Stability: Resistant to strong acids (except concentrated sulfuric acid) and organic solvents

- Dimensional Stability: Shrinkage rate 0.1-0.5%, thermal expansion coefficient similar to aluminum metal

- Flame Retardancy: UL94 V-0 rating, halogen-free flame retardant

What Products Can Be Made with PEEK Injection Molding?

Although PEEK injection-molded parts are costly, they are irreplaceable in these high-performance applications:

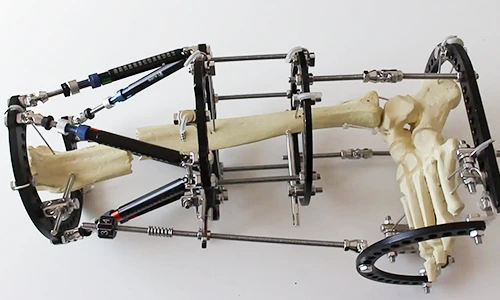

Medical Field

Application

- Spinal fusion cages

- Endoscope sealing heads

- Pacemaker housings

Why?

- Biocompatibility: No rejection for long-term implants (FDA-certified)

- X-ray transparency: No interference with postoperative imaging

Aerospace

Application

- Satellite fuel valve seats

- Aircraft wire harness connectors

- Drone motor brackets

Why?

- 30% weight reduction: Equivalent to 5% fuel efficiency improvement

- Cryogenic resistance: Maintains strength at -60°C

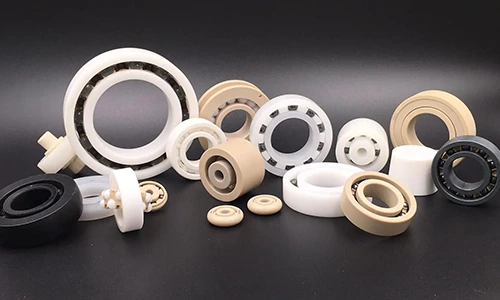

Industrial Equipment

Application

- Chemical pump seals

- Food processing bearings

PEEK injection molding can also produce precision valve cores for coffee machines, foldable smartphone hinges capable of over 100,000 open/close cycles, and deep-sea drone housings that withstand high-pressure underwater environments. With the continuous development of products in AI and robotics, the role of PEEK injection molding will become even more prominent.

PP

PE

PC

PVC

ABS

PA

POM

PBT

PMMA

PEEK

When Can You Avoid Using PEEK Material?

If your product design faces limited budget, material shortages, or performance overkill, these alternatives might be more cost-effective.

Scenario 1: Limited Budget – Can a Cheaper Material Be Used?

Criteria: When your part operates below 150°C and does not contact strong acids / alkalis.

Recommended Solution:

Alternative: PEI (cost reduced by 30%-40%)

Real-World Case: After switching to PEI for an industrial gearbox:

- Costs reduced by 35%

- Stable operation for 5 years in 120°C lubricant environments.

Scenario 2: PEEK Material Shortages – What to Do?

Emergency Solutions (priority order):

- PEKK: Closest performance to PEEK but requires increasing molding temperature by 10-15°C.

- PPS: Short-term alternative for non-load-bearing structural parts.

- High-Temp Nylon: Only for temporary use (lifespan reduced by 50%).

Comparing PEEK injection molding and PEI injection molding

The core of comparing PEEK and PEI in the field of injection molding lies in their performance and cost. Both plastics exhibit high temperature resistance, corrosion resistance, and similar properties. While their performance is comparable, there is a significant cost difference (typically, PEEK is 2-3 times more expensive than PEI). Although other plastics (e.g., PPS, LCP) may partially match their performance, they cannot replace PEEK and PEI in critical metrics (e.g., biocompatibility, long-term fatigue resistance). Therefore, engineers must balance performance and cost to select the optimal material.

| Dimension | PEEK | PEI | Design Decision Points |

| Thermal Performance | Continuous use temp: 250°C | Continuous use temp: 170°C | PEEK is mandatory for high-temperature environments (>200°C). |

| Melting point: 343°C | Tg: 217°C | ||

| Mechanical Performance | Tensile strength: 100 MPa | Tensile strength: 85 MPa | Choose PEEK for high-load applications; PEI for impact resistance. |

| Flexural modulus: 3.6 GPa | Flexural modulus: 3.0 GPa | ||

| Processing Parameters | Barrel temp: 360-400°C | Barrel temp: 340-370°C | PEI has shorter cycle time and suits thin-walled complex parts. |

| Mold temp: 160-180°C | Mold temp: 140-160°C | ||

| Chemical Compatibility | Resistant to strong acids (except concentrated H₂SO₄) and organic solvents | Resistant to fuels and weak acids; poor alkali resistance | Use PEI for fuel exposure; PEEK for harsh chemical environments. |

| Cost & Process Challenges | Material cost: High | Material cost: Medium | Prioritize PEI under budget constraints but avoid prolonged heat exposure. |

| Requires high-temp molds to prevent cold slugs | Prone to flash; requires precise pressure control | ||

| Key Applications | Oil seals, surgical tools, satellite components | Automotive sensor housings, PCB insulators, steam-sterilized equipment | Use PEEK for medical implants; PEI for electronics encapsulation. |

How to Choose a Reliable PEEK Injection Molding Service Provider?

It involves many challenges for startups or design companies to find a PEEK injection molding supplier:

- High-precision parts production within tight deadlines

- Trial-and-error cost management under limited budgets.

It can lead to severe consequences when choosing an unqualified PEEK processor. For example, a rumored medical company once partnered with a molding factory that deviated by just 2℃ in temperature control, causing $1.2 million worth of implant components to crystallize and embrittle in bulk, delaying the project by over six months.

1. High-Temperature Precision Molding Expertise

PEEK molding requires maintaining a melt temperature of 380-400℃ consistently. Retrofit equipment in generic factories often suffers temperature fluctuations exceeding ±5℃. First Mold employs all-electric injection machines with closed-loop temperature control and achieves stability within ±1.5℃. In 2024, 13 out of 17 PEEK projects involved ultra-thin walls, achieving a first-shot success rate of 92%+ thanks to this precision.

2. Uncompromising Material Traceability

Approximately 35% of so-called “PEEK” parts on the market are adulterated with cheaper PEI or PPSU. Reputable suppliers provide UL certification for every material batch. FirstMold not only discloses raw material test reports but also allows clients to participate in third-party FTIR spectroscopy verification, eliminating counterfeit risks at the source.

3. Risk-Controlled Agile Response

When a robotics company urgently needed to redesign PEEK joint molds within 48 hours due to design changes, First Mold leveraged pre-engineered modular hot runner systems to slash mold modification time from the industry average of 72 hours to just 19 hours. This agility is powered by a standardized database of 50+ PEEK-dedicated mold designs.