Home / PPS Injection Molding

PPS Injection Molding

Get your parts with outstanding mechanical properties by our PPS injection molding

- Engineering plastic with excellent heat resistance

- PPS Engineered for Extreme Conditions

- High Strength, Lightweight Solutions

Overview of PPS Injection Molding

PPS injection molded parts possess excellent thermal stability. PPS is a flame-retardant material, with flame resistance superior to that of most engineering plastics. Due to PPS’s good affinity with glass fibers, carbon fibers, inorganic fillers, and solid lubricants, it shows enhanced properties after modification. Therefore, the pellets used in injection molding are primarily modified and reinforced with various fibers and inorganic fillers.

Although the price of PPS is relatively high, its excellent properties have increasingly garnered market favor in recent years. FirstMold has amassed extensive experience in PPS injection molding over the past decade, with cases spanning various industries. We can quickly respond to and perfectly resolve any defects that may arise in PPS injection molding.

Applications of PPS By Injection Molding Method

PPS material is widely used in various applications, including automotive engine covers and electronic and electrical components such as coolant systems, fuel injection systems, and thermostat housings. In the industrial sector, it is used for various precision machinery components, such as valves and pipes. In the heating, ventilation, and air conditioning (HVAC) industry, polyphenylene sulfide is used in compressors, mufflers/accumulators, and more.

According to estimates by Market.US, the global PPS market size is expected to reach $3.3 billion by 2032, with the Asia-Pacific market accounting for over 40% of the global share.

Automotive & EV

- Engine covers

- Coolant system components

- Thermostat housings

- Transmission components

- Brake system components

- Ignition system parts

- Air intake manifolds

Electronics and Electrical

- Connector housings

- Transformer bobbins

- Relay components

- Circuit breaker parts

- LED light housings

- Insulation components

- Power module housings

Medical

- Sterilization trays

- Dental equipment components

- Fluid delivery systems

- Diagnostic equipment parts

- Respiratory equipment parts

- Catheter components

- Blood analyzers

Agriculture Machinery

- Valve bodies

- Pipe fittings

- Compressor parts

- Bearings

- Filter housings

- Conveyor parts

- Gear wheels

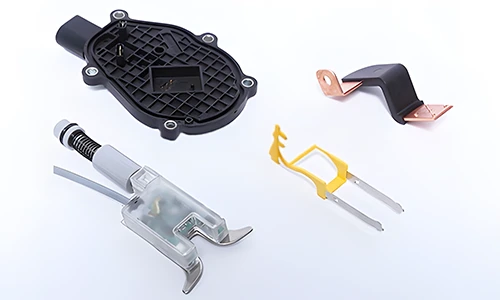

Here are some past PPS injection molding projects by FirstMold(Each project is more than five years old.):

PP

PE

PC

PVC

ABS

PA

POM

PBT

PMMA

PEEK

PPS Injection Molding Capabilities

Our injection molding capabilities for PPS(Polyphenylene sulfide) materials come from the following sources:

Equipment:

Material Expertise:

Wide Range of Solutions:

Design Support:

Problem-Solving:

Quality Assurance:

Years of Experience in PPS Injection Molding

FirstMold has completed hundreds of PPS injection molding projects, serving a wide range of industries including automotive, aerospace, medical, healthcare, and consumer electronics, showcasing extensive experience.

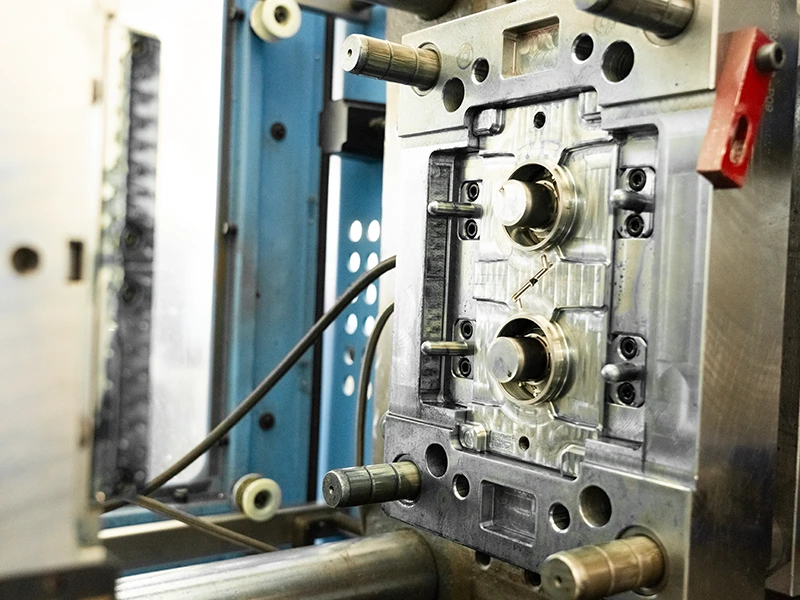

Perfect Mold Design

FirstMold’s experienced mold designers can create perfect molds specifically for PPS materials, regardless of the complexity of the injection molded parts’ structure.

High Production Volume

Leveraging the production capacities of its factories in China and Mexico, FirstMold can easily achieve a monthly production volume of over 10 million PPS products.

PPS Injection Molding Cases

This case shows a seemingly simple but not easy to complete the mold design and molding production of automotive sunroof rail parts.