Home / Manufacturing Services / Mold Making Service / Rapid Tooling Making Service

Rapid Tooling Making

When you need to conduct market tests as soon as possible, rapid tooling is your best choice.

Rapid tooling and the subsequent rapid injection molding complement each other, and it can make parts for you at a race-against-time speed. You will have a comprehensive understanding of the cost, materials, structure, appearance and market response of the product you’ve designed with rapid molds.

What is a rapid tooling?

Rapid tooling (also called prototype tooling, bridge tooling, soft tooling, or low-volume mold) helps you test products quickly and cheaply. It’s perfect for small-batch production (costs 60%-80% less than mass-production molds). People use it to check product functions, review designs, improve structures, and calculate costs. During the process, the data you get can help finalize your high-volume production plan.

Unlike production toolings, rapid toolings have shorter lifespans (typically 100-10,000 injection cycles). However, they offer shorter lead times (5-28 days) and adapt to design changes easily. They save time and money, cut risks, and work best for prototype testing, bridge manufacturing, and low-volume orders in most sectors.

What Can First Mold’s Rapid Tooling Bring to Your Design?

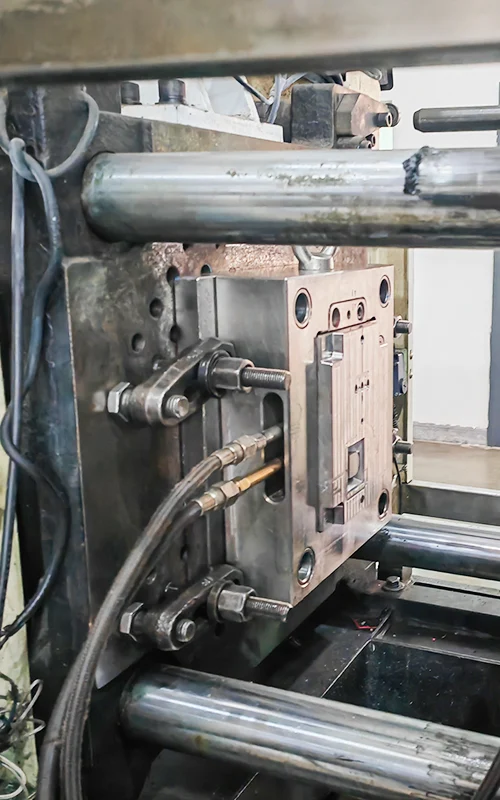

For clients with existing molding equipment, we also provide custom tooling-only solutions. With First Mold’s in-house 5-axis CNC machines, EDM equipment, and mold fabrication workshops, the rapid molds we make will be your best choice.

Full In-House Control, 0 Outsourcing Risks

- Advanced 5-axis CNC, EDM unit ensure 100% in-house production. No delays or errors from third-party vendors.

- Optimize mold design and molding parameters collaboratively. No finger-pointing between external suppliers.

Precision & Longevity, Both Enhanced

- 5-axis CNC machining paired with CMM inspection achieves industry-leading ±0.02mm precision

- Extend mold lifespan to 10,000+ cycles with TiN coatings or H13 tool steel.

Transparent Pricing, No Hidden Costs

- Cost based on mold complexity (sliders, ejector pins, etc.), offering 15%-20% savings versus competitors.

- Optimize designs upfront with Design for Manufacturability (DFM) reports to minimize revisions.

When to Choose Rapid Tooling: Rapid Tooling vs. Production Tooling

Rapid tooling and production tooling are complementary solutions. Your choice should depend on product development stage, budget, and volume needs. Below is a concise comparison to guide your decision.

| Key Factor | Rapid Tooling | Production Tooling |

| Stage | Prototyping, low-volume batches, market testing | Mass production (10,000+ units) |

| Mold Cost | 1,000−20,000 | 20,000−100,000 |

| Lead Time | 5-28 days | 8-16 weeks |

| Mold Lifespan | 100-10,000 cycles | 100,000-1,000,000+ cycles |

| Design Flexibility | High (easy gate/cooling adjustments) | Low (costly modifications) |

Typical Scenarios for Rapid Tooling:

- Testing a New Product: Test 50-500 functional prototypes within 3 weeks.

- Frequent Design Changes: Frequent adjustments (e.g., consumer electronics upgrades).

- Avoid Overstock: Produce 1,000-5,000 units to avoid overstock risks.

Typical Scenarios for Production Tooling:

- Mass production: Scale to 100,000+ units for cost efficiency.

- High precision/durability: Automotive parts or medical device molds requiring extreme longevity.

- Long-term demand: Stable orders lasting 3+ years (e.g., appliance components).

A good rapid tooling can accept multiple verifications

Rapid Tooling Manufacturing Process

Through 4 steps, you can obtain a high-quality prototype tooling.

1. 3D Model Upload & DFM Review

Upload your 3D design file. Our engineers deliver a DFM report within 48 hours. They will flag issues like uneven wall thickness or insufficient draft angles.

2. Mold Design & CNC/EDM Machining

Customize mold structure (parting lines, gates, cooling channels). 5-axis CNC machines and EDMs will produce core/cavity in 3-7 days with ±0.03mm precision.

3. Surface Polishing & Assembly

Polish surfaces (mirror or texture finishes), deburr parts, and assemble molds in workshops. Critical dimensions are verified using CMM with ≤0.02mm tolerance.

- Recommended

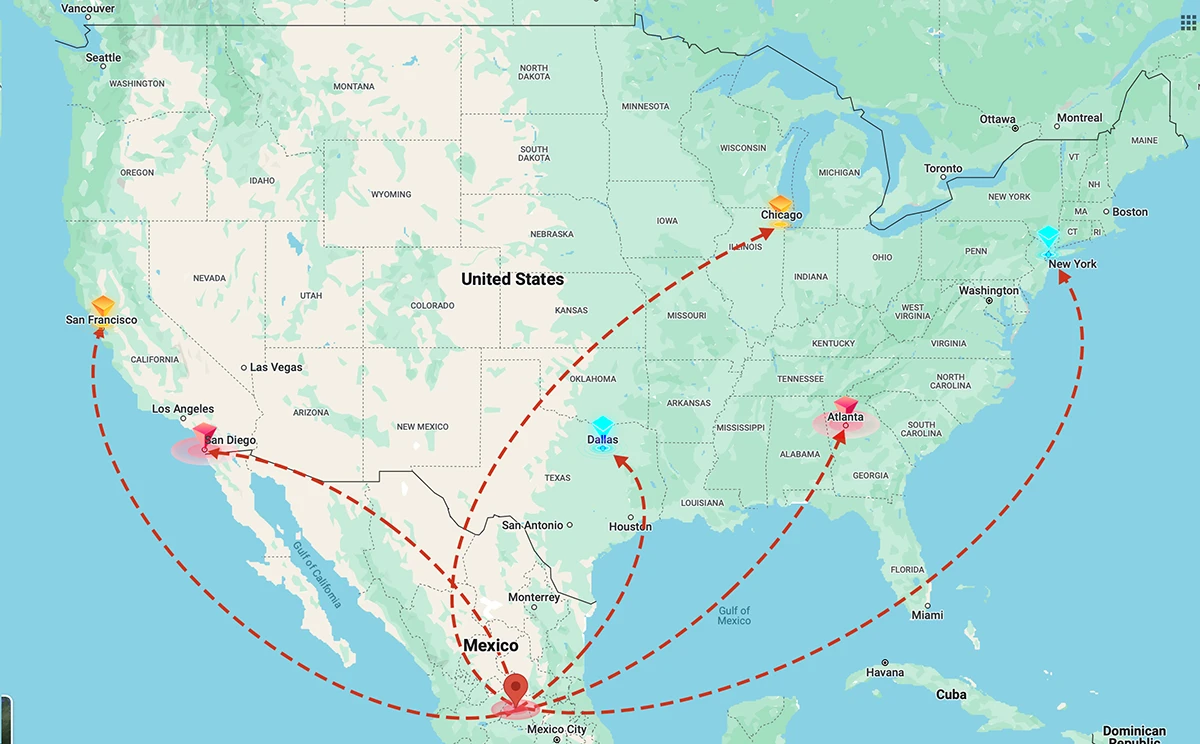

Mexican Rapid Tooling Making Services for North American Buyers

Rapid tooling at Firstmold is low cost, short time consuming, and you can find unreasonable in the design in time before mass production so that the engineering R&D personnel can check the problem visually on it, and then make corrections on the drawings to improve the service life of the production tooling.

Our rapid tooling services are designed to cater to clients worldwide. For our North American customers, we highly recommend placing orders through our Mexico facility.

Fast

Easy to modify

FastEasy to get materials

Surface finishes available

Rapid Tooling Materials

Aluminum Molds (6061/7075)

This is ideal for low-volume batches (100-5,000 parts) like consumer electronics housings or automotive prototypes. First Mold uses 5-axis CNC machining for faster turnaround (5-15 days).

Steel Molds (P20/H13)

This is built for 10,000+ cycles in demanding applications (medical devices, connectors). Enhanced with TiN coatings to resist wear and reduce downtime.

Materials for Rapid Injection Molding: What We Can Produce

Rapid injection molding relies on molds produced via rapid tooling technologies. This seamless process allows fast material testing and low-volume production.

- ABS: Durable housings (e.g., smartwatch cases).

- PP: Hinges, food containers.

- TPU: Soft grips (e.g., headphone ear pads).

- PC: Transparent covers (e.g., LED diffusers).

- POM: Gears, sliding parts.

- PEEK: Aerospace valves, chemical seals.

- Nylon: Functional prototypes (e.g., drone arms).

- PEI: Medical sterilizable trays.

- PA: Gears, bearings, structural parts

- PMMA: Light guides, lenses, displays

- PS: Disposable cutlery, labware

The application scenarios of rapid tooling

Electronics Industry

Case:

- Client Needs: Deliver 500 test units in 3 weeks, budget under $6000.

- Solution: Aluminum tooling (cost: $4000) + fast-cycle molding.

- Results: Shipped in 18 days, 98% defect-free rate, saved 30% on tooling costs.

Auto Components

Case:

- Pain Point: Product launch was in 8 weeks.

- Solution: Additive manufacturing tooling + small-batch production.

- Results: Completed design-to-assembly in 6 weeks, 75% cheaper than hardened steel molds.

Healthcare Equipment

Case:

- Critical Requirements: ±0.05mm tolerance, medical-grade PC material.

- Solution: Hardened steel tooling (H13) + precision CNC machining.

- Results: 100% first-article approval, 100,000+ injection cycles lifespan.

Industrial Machinery

Case:

- Challenge: Thin-wall design (0.8mm) caused warping; 3 failed trials with standard tooling.

- Solution: Optimized cooling channel layout + 5 trial runs for parameter tuning.

- Results: Mass production yield jumped from 70% to 95%.

Rapid Tooling Case Gallery

Rapid Tooling FAQ

What file types do you accept for mold design?

We accept: STEP (.stp), IGES (.igs), and SolidWorks (.sldprt) files.

Best choice: Use STEP files. They keep full 3D data for smooth processing.

Avoid: PNG JPG files. We need 3D files.

Need help? Send your file. We check it free in 24 hours.

How many parts can a rapid mold produce?

Aluminum molds: 1,000-5,000 plastic parts (e.g., phone cases, 300g PP material).

Steel molds: 10,000-50,000+ cycles (e.g., medical syringe parts, PEEK material).

3D-printed molds: 50-300 cycles (e.g., silicone rubber prototypes).

Tip: Higher injection pressure (over 80MPa) reduces mold life by 20-30%.

What if my parts have complex geometries?

We handle:

- Undercuts (e.g., snap-fit tabs).

- Thin walls (0.5mm thick, like drone arms).

- Micro-textures (Ra 0.8μm mirror finishes).

Solutions:

- Use 3D-printed molds (SLS/MJF technology) for ±0.15mm tolerance.

- Add side sliders to aluminum/steel molds (costs 15% extra).

Example: Made 200 nylon gears with 0.6mm teeth in 10 days.

Do you offer global shipping?

Yes! We ship to 50+ countries via DHL/FedEx.

Cost included: Mold packaging and basic insurance.

Delivery time:

- Asia: 1-3 days.

- Europe/USA: 3-5 days.

- Tracking link sent after shipment.

Customs help: Provide HS codes and commercial invoices.

How accurate are rapid molds?

Standard precision: ±0.05mm (for most ABS/PC parts).

High precision: ±0.02mm (steel molds with EDM finish, e.g., connector pins).

How we do it:

- Check molds with CMM machines (Mitutoyo Crysta-Apex).

- Run 5 test shots to verify dimensions.

Data: 98% of molds pass ISO 2768 medium tolerance.