Home / Manufacturing Services / Mold Making Service / Production Tooling

Production Tooling Making Service | Essential for Mass Molding

Production tooling is mainly used for mass-producing high-precision and highly stable product parts during the injection molding process.

With rich experience and cutting-edge technology, First Mold offers a durable and high-precision production tooling making service. Through innovative mold design and high-quality material selection, we can keep the costs under control.

Production Solutions For You

Once the rapid tooling phase is complete, your product will move on to mass production, and that’s where our production tooling services come in handy. Injection molding, blow molding, extrusion, die casting, forging molding, stamping and other types of molds are the products of our production mold services.

Firstmold’s production tooling service has been cultivated in this industry for many years, representing the level of Chinese industrial manufacturing, and has been widely praised by our customers.

Mold Design

- Designer Staffs: 10. Monthly design of 30 sets of molds;

- Advanced design concepts and services, including automatic design, automatic programming and in-line inspection.

- Application software contains: UG, AUTO-CAD, CATIA , MOLDFLOW

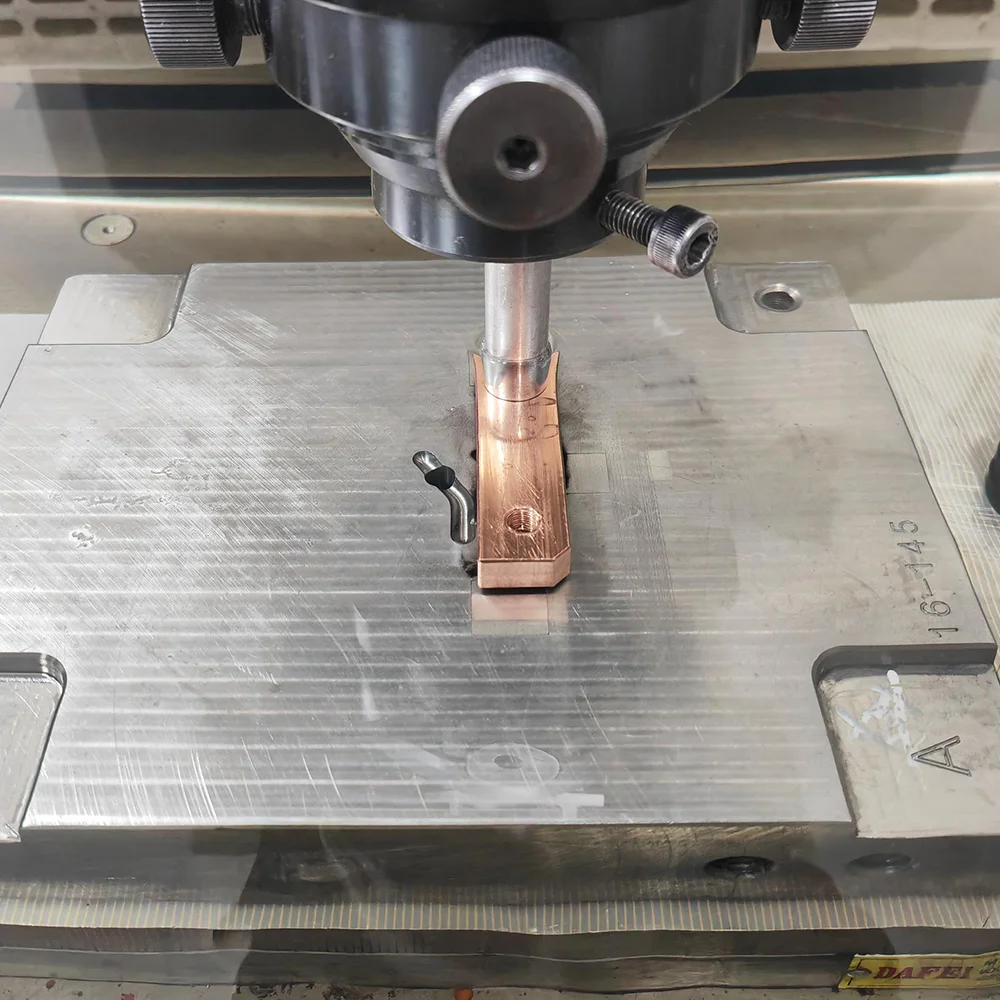

Mold Making

- World-class equipment and superior precision

- Stable accuracy allows for reproducibility and interchangeability of parts.

- The introduction of automated processing has greatly increased production capacity and efficiency.

- Monthly mold making: 25 sets

Mass Production

- Equipment models: from 90 tonage to 1000 tonage

- Advanced equipment and perfect management system in the industry

Quality Control

- ISO9001:2016 system, IATF 16949 for the automotive industry

- IPQC reduces the error rate and waste during mould processing.

- Quality control ensures that the final product meets the requirements and expectations of the customer.

- Special product arrangements for full inspection.

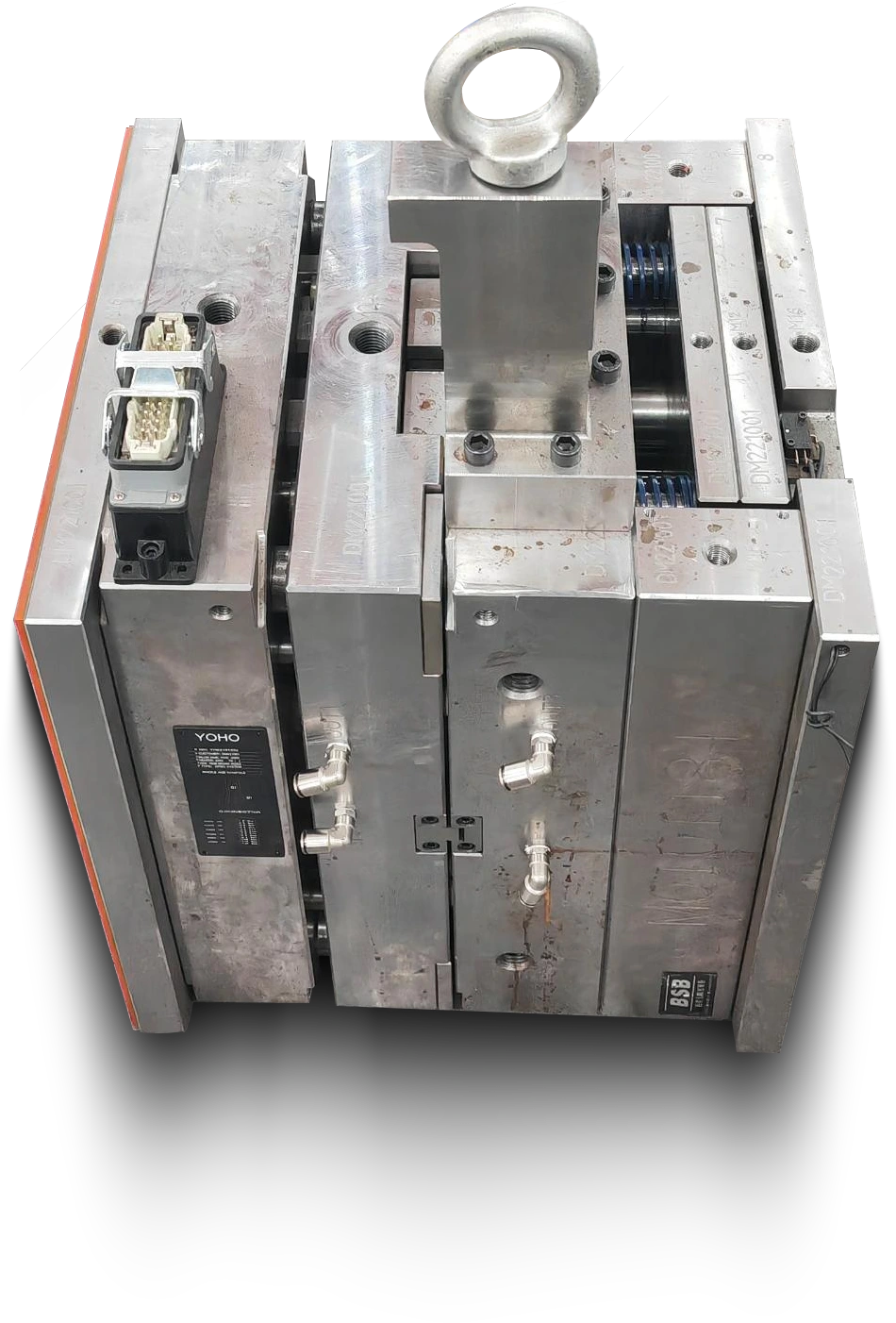

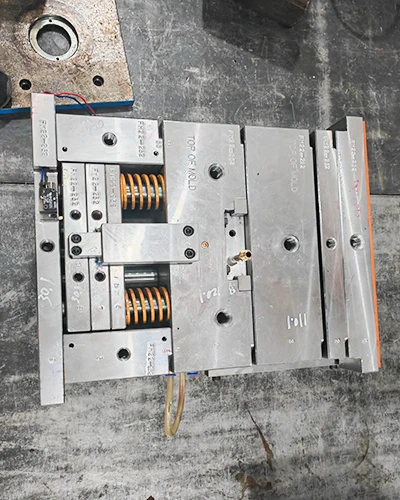

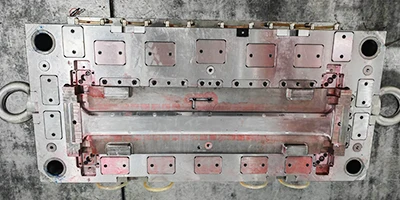

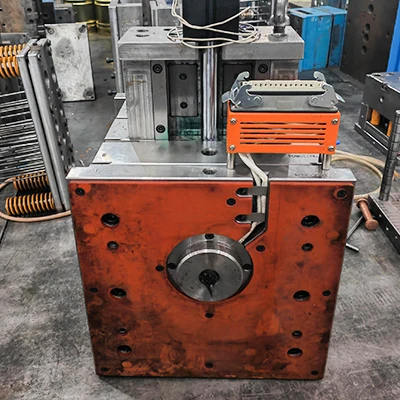

Production Tooling Gallery

About Us

Mold Classifications and Standards

Production toolings are used for mass production, so there are strict requirements for the cycles. At Firstmold, mold size, construction, and material determine the final price of production toolings, while the material determines their lifespans. We have procurement staff to control the quality of materials and inspectors to repeatedly control the performance of our products, so we are fully committed to your products.

SPI Finish Grade | General Mold Material | Estimated Usage Times (Approximate) |

A-1 | High – quality tool steel (e.g., P20, H13) | 500,000 – 1,000,000 cycles |

A-2 | Good – quality tool steel (e.g., P20, modified alloy steel) | 300,000 – 800,000 cycles |

B-1 | General – purpose tool steel (e.g., standard alloy steel) | 200,000 – 600,000 cycles |

B-2 | Medium – grade alloy steel | 100,000 – 400,000 cycles |

C-1 | Low – cost alloy steel or some cast iron materials (if applicable) | 50,000 – 200,000 cycles |