Home / Hot Runner Mold Making

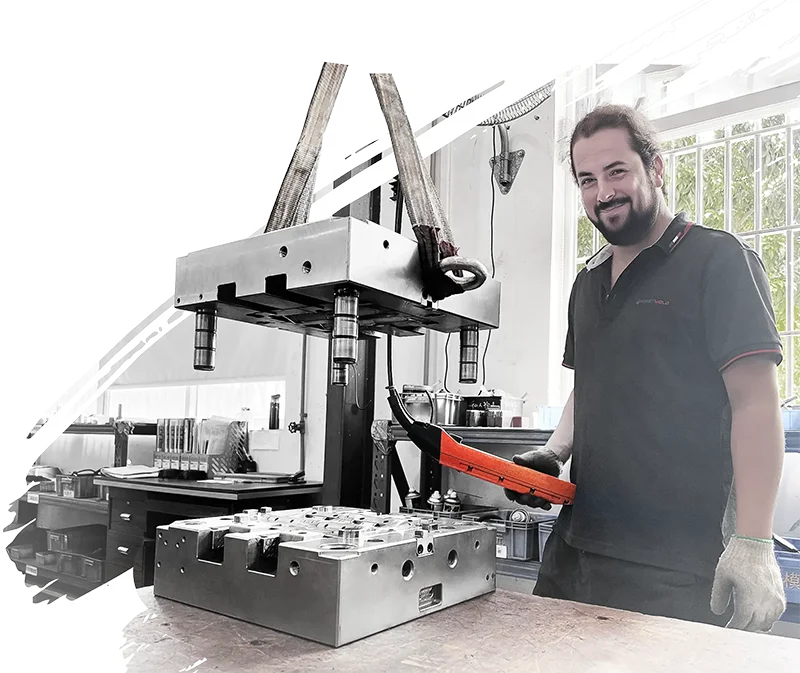

Hot Runner Mold Manufacturing

Zero Waste, Faster Cycle Times, 100% Automated!

Custom hot runner systems with ≤0.05mm tolerance, proven in 500+ projects across 20 countries.

- With real-time viscosity monitoring & PID-controlled heaters

- Global technicians on standby for nozzle blockage or leakage

- Using pre-engineered modules (HASCO/DME standards)

If needed, we can sign an NDA agreement before providing the quote.

What is a Hot Runner System?

A hot runner system acts as a “temperature-controlled highway” for molten plastic, eliminating cold runners to save 15-40% material waste in high-volume production. Unlike traditional cold runners, its heated components (nozzles, manifolds) maintain resin at optimal viscosity, enabling cycle times as fast as 5 seconds for thin-walled parts like medical syringes or microelectronics.

Injection mold design and manufacturing directly affect the final product’s quality, production efficiency, and cost. In traditional injection molding processes, cold-runner molds can lead to uneven plastic flow and material wastage. This issue becomes particularly significant when producing high-precision products, as cold-runner technology may compromise molding quality and product consistency.

As market demands for higher product quality and production efficiency have grown, hot-runner mold technology has emerged as a breakthrough solution to overcome the limitations of traditional molds. By utilizing precise temperature control and intelligent regulation systems, hot-runner technology ensures that plastic flows more uniformly throughout the injection process, thereby enhancing molding quality while reducing both production costs and material waste.

Industry Solutions

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scramble.

- Research beyond the business plan

- Marketing options and rates

- The ability to turnaround consulting

- Help companies into more profitable

There are many variations of passages of available but the majority have suffered alteration in that some form by injected randomised lorem ipsum is simply free text available in the market words which don’t look even as slightly believable now.

There are many variations of passages of available but the majority have suffered alteration in that some form by injected randomised lorem ipsum is simply free text available in the market words which don’t look even as slightly believable now.

There are many variations of passages of available but the majority have suffered alteration in that some form by injected randomised lorem ipsum is simply free text available in the market words which don’t look even as slightly believable now.

Petroleum and Gas

Indsutrial Construction

Chemical Research

Mechanical Engineering

Power Enegries

Bridge Construction

Download Our Brochure