Home / Manufacturing Services / CNC Machining Service / CNC Milling Service

CNC Milling Services | Top Choice For Global Customers

This might be the most reliable milling service you’ve ever come across. From ideas to actual products, a mature system will safeguard the whole process, making it possible for you to get unique parts.

Providing good alternative options for rapid prototypes.

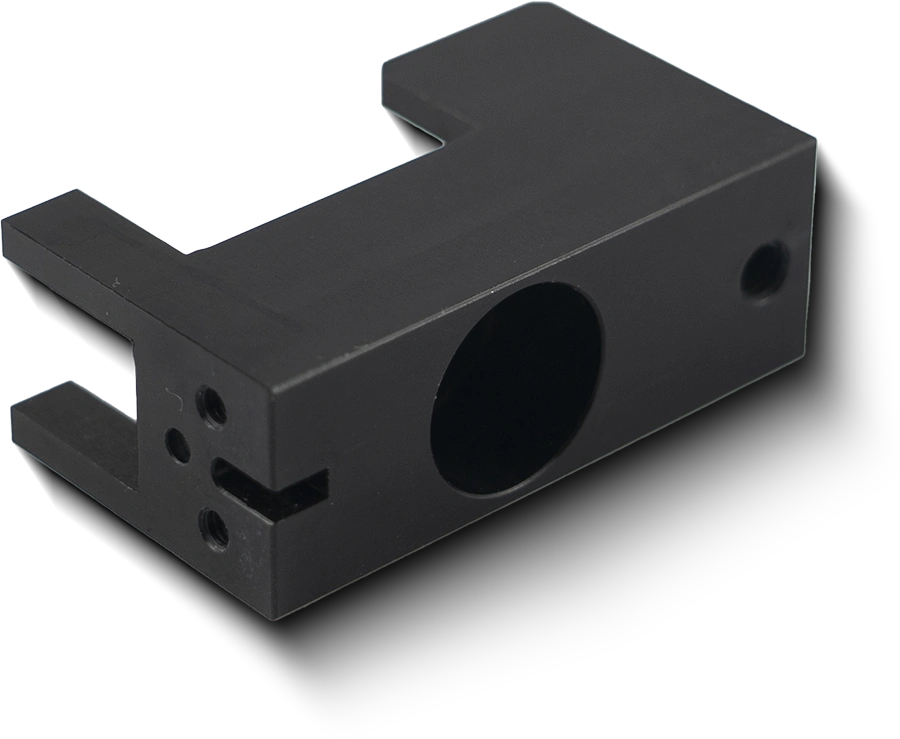

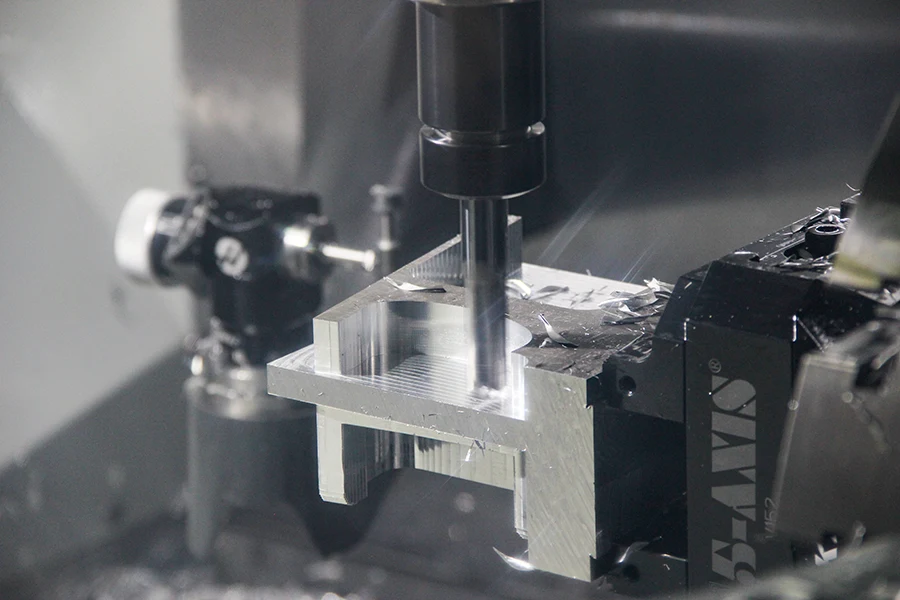

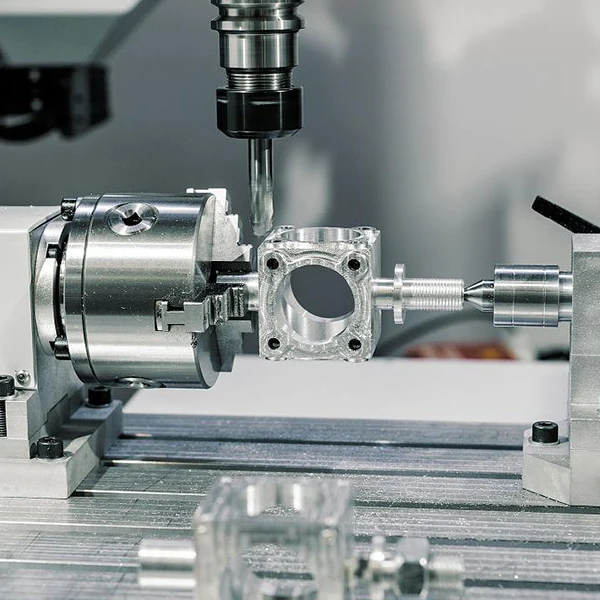

Our 40+ milling machines, including 3 axis, 4 axis, and 5-axis CNC milling centers, are capable of producing rapid prototypes and low-volume units of precision parts with high functionality and complex geometries. CNC milling is ideal for creating parts with flat and jagged geometries like slots and grooves, as well as for post-machining to add details to turned, 3D-printed or molded parts.

We specialize in making functional parts like brackets, gears, fittings, enclosures, housings, mold tooling, engine parts, medical instruments, punches, and dies, making it an ideal fit for use across many industries.

Tight Tolerance

Creative Design

Mass Processing Available

Industries We Can Mill For

Our Advantages and Benefits in Milling

Precision

Our 3-axis, 4-axis, and 5-axis CNC milling centers ensure precision and accuracy to within ±0.001″. This is critical in industries such as aerospace, medical, and automotive where precision is paramount.

Speed

With our 40+ milling machines and skilled machinists, we can produce parts quickly and efficiently without sacrificing quality.

Complex Geometries

Our CNC milling service is ideal for producing complex parts with intricate geometries, such as slots, grooves, and other custom features.

Material Diversity

We can mill a variety of materials including metals, plastics, and composites to fit your specific needs.

Design Flexibility

Our experienced engineers and machinists can provide design input to help optimize your parts for production, and can even produce low-volume custom parts with short lead times.

Cost-Effective

With our streamlined process and advanced machinery, we can provide cost-effective milling solutions without sacrificing quality or accuracy.

Our Milling Capability

Mills

40

Department Headcount

60

Monthly Production

100,000 units

Tolerance Standard

ISO-2768-M (for both metal and plastic)

Maximum Tolerance

±0.0254mm (±0.001″)

Maximum Milling Width

800mm (31.50″)

Maximum Machining Height

800mm (31.50″)

Maximum Machining Depth

200mm (7.87″)

Minimum Machining Dimension

5mm x 5mm x 5mm (0.2″ x 0.2″ x 0.2″)

Maximum Machining Depth

200mm (7.87″)

Fastest Delivery Time

3-7 Days

We are trusted by many clients

Ordering Process

Upload Your Design File

Submit your design file to initiate the process.

Choose Materials & Techniques

Select the materials for your product.

Instant Quotation & Ordering

Get a quote instantly and submit your order.

Precision Milling Taken Care

Leave the production to our capable hands.

Receive Your Item On Time

Get your finished item delivered to you.