Home / Manufacturing Services / CNC Machining Service / CNC Precision Machining Service

CNC Precision Machining Service | Strict Workpiece Quality Control

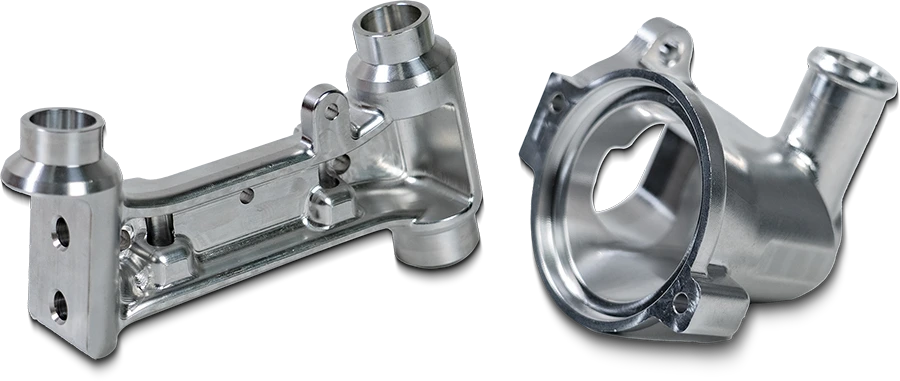

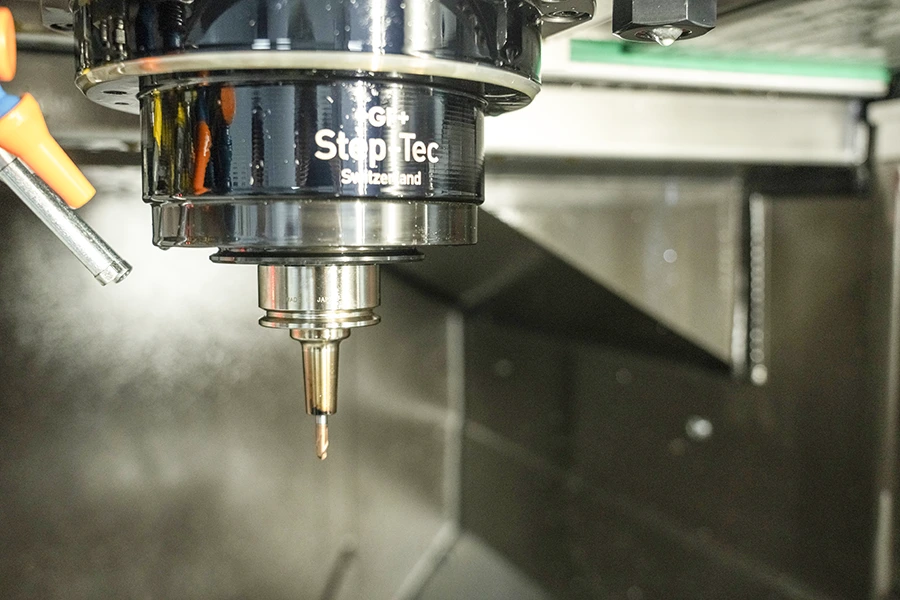

CNC precision machining service that is more meticulous than ordinary CNC processing, using top-level machining equipment and the ultimate surface polishing techniques.

Tailor-made for high-precision and complex parts

Firstmold’s precision CNC machining, compared to ordinary CNC machining services, has reached the pinnacle of precision. Parts requiring such high precision mostly come from industries like precision molds, aerospace products, and medical device products.

Precision CNC machining requires extremely high-precision equipment, the purchase of which often requires a significant amount of money. Additionally, it requires operators to have ample experience. Therefore, the price of our CNC precision machining services will be more expensive. Of course, you will also receive the high-precision parts you desire.

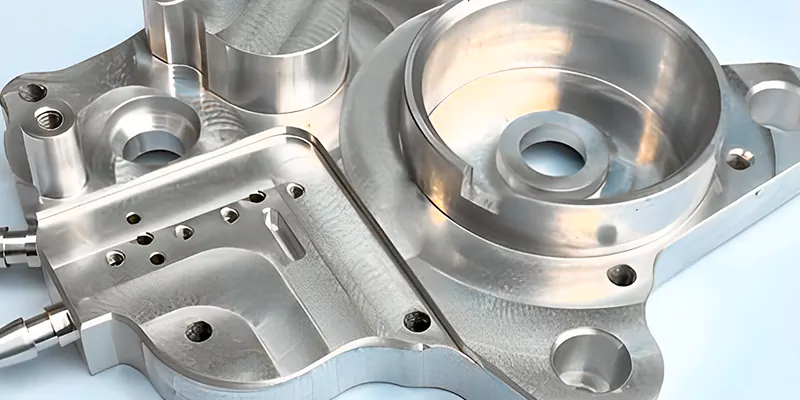

High precision

Tight tolerance up to ±0.005mm

Complex Structure

Our hobby is to take on the challenge of complex structural parts

Smooth Surface

surface roughness is down to RA0.9 μm

Mass production available

There is no limit to the number of precision parts we can process

FirstMold's CNC Precision Machining Application

Precision Mold Machining

What we call mold accuracy includes: dimensional accuracy, shape accuracy, position accuracy, and surface accuracy. Among them, it is especially important to measure the position accuracy of the cavity and the core. With our CNC precision machining, high-precision molds can be made easily for your subsequent injection or die-casting of high-precision products.

High Precision

High Load-bearing Capacity

Little Wear and Tear

Interchangeability Available

Aerospace CNC Precision Machining

Aerospace components undergo tremendous stress, including high speeds, high temperatures, and high pressure. Deviating from these tolerances even slightly can cause catastrophe. The control of dimensional tolerances allows the components to operate under severe conditions.

- Ensures safety and reliability under extreme conditions.

- Optimizes performance for fuel efficiency and aerodynamics.

- Enables component interchangeability and maintenance.

- Extends equipment longevity and durability.

Medical Device CNC Precision Machining

Many medical devices have critical life-saving functions or require extremely high precision to be effective (such as surgical instruments, diagnostic equipment). Therefore, precision CNC machining is necessary to ensure the commitment to patients.

- Guarantees patient safety and device biocompatibility.

- Secures functionality and efficacy for life-saving applications.

- Maintains integrity and sterilization compatibility.

- Complies with stringent regulatory standards for public health.

4 Steps To Build Customized cooperation

Having completed hundreds of projects, we are experienced in handling high-precision and complex parts. We can provide you with quality and reliable CNC precision parts machining in a short period of time, and the process can be completed in just four steps.

1. Drawings or Samples

You can customize drawings and samples to provide industry solutions

2. Review and Quote

Confirm production process and quotation, place an order for your requirement

3. Handling and Proofreading

Inspection, proofreading, your confirmation of the parts or products

4. Production

Testing, processing, quality control, packing and shipping