Home / 4 Axis & 5 Axis CNC Machining Service

4-Axis & 5-Axis CNC Machining Services

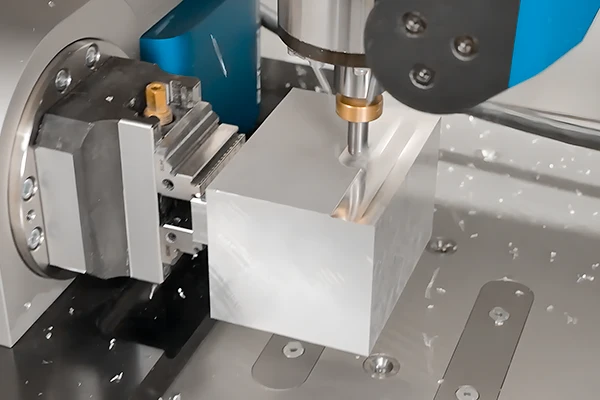

First Mold’s tariff-optimized 4-axis & 5-axis machining services deliver high-precision components for aerospace, automotive, and medical industries worldwide. Achieve ±0.001mm tolerances and faster customs clearance through our double supply chain hubs, ensuring cost predictability for both prototyping and production volumes. ISO 13485 & IATF 16940 certified, 1-5 day lead times.

What is 4-Axis and 5-Axis Machining?

4-axis and 5-axis machining represent advanced evolutions of 3-axis CNC technology. 3-axis CNC machining controls tool movement along three linear axes: X (left-right), Y (front-back), and Z (up-down). People can get efficient processing of over 90% of prismatic components, such as equipment enclosures and mold bases.

When features like keyways or threaded holes need machining on rotational surfaces, 4-axis machining enhances 3-axis systems by adding the A-axis—a rotary motion allowing the workpiece to rotate around the X-axis. This innovation eliminates repeated workpiece repositioning, enables 360° machining in a single setup, and improves production efficiency by approximately 35%.

5-axis machining introduces the B-axis—a tilting mechanism where the cutting tool pivots around the Y-axis (±30°–120°). Combined with workpiece rotation, this allows multi-angle cutting for complex geometries like aerospace turbine blades and injection mold cavities.

The 3-axis remains the most cost-effective solution for prismatic parts. The 4-axis addresses multi-face machining for rotational bodies, and the 5-axis overcomes challenges in intricate surface fabrication. Validated by 2,500 case studies at First Mold, strategic axis selection reduces per-unit costs by 15–40%.

Why Choose 4-Axis & 5-Axis CNC Machining Services?

There’s a growing need to make super-detailed and complicated parts (like curves on multiple angles or deep hollow spaces). Traditional 3-axis CNC machining technology can’t handle these well, but multi-axis machines with spinning worktables can easily solve these problems!

4-Axis CNC Machining Benefits

1. Enhanced Rotation Efficiency

- Machine gears/shafts in one clamp

- 35% faster vs 3-axis (e.g., auto driveshafts: 8h→5.2h)

2. Affordable Curved Surface Work

- Best for mid-curve molds (R≥15mm)

- Costs 40-60% less than 5-axis machines

3. Batch Precision Guaranteed

- ±0.01mm repeat accuracy (engine blocks: ≤8μm errors)

5-Axis CNC Machining Advantages

1. Complex Shapes in One Setup

- Cut multi-angle features like turbine blades (defects ↓26%)

2. Medical-Grade Finishes

- Achieve Ra<0.4μm surfaces (bone implants ready)

3. Smart Cost Control

- Use 1 fixture instead of 12 (aircraft parts)

- Deliver complex molds in 4 days vs 7 days

3-Axis vs. 4-Axis vs. 5-Axis CNC Service

| Feature | 3-Axis Service | 4-Axis Service | 5-Axis Service |

| Axis Movement | X, Y, Z (linear axes) | X, Y, Z + 1 rotational A-axis | X, Y, Z + 2 rotational A+B axes or A+C axes |

| Complexity | Simple geometries | Moderate complexity | High complexity |

| Precision | Good for basic tolerances | Better for multi-sided parts | Highest precision |

| Cost | Lowest | Moderate | Highest |

| Lead Time | Shortest | Moderate | Longer |

| Pros | Affordable, easy to operate | Reduced setups for multi-face work, better detail than 3-axis | Single setup for complex parts, superior surface finish, tighter tolerances |

| Cons | Limited to simple shapes, manual repositioning needed | Slower than 3-axis for simple jobs, higher skill requirement | Expensive machines, requires expert programmers |

Quick Selection Guide

Pick 3-Axis When:

- Making simple flat parts (metal plates, brackets)

- Tolerances ≥±0.02mm OK

Switch to 4-Axis If:

- Creating round parts (gears, camshafts)

- Need basic curves on budget

Go 5-Axis For:

- Aerospace parts (titanium frames)

- Medical tools (bone implants)

- ±0.005mm ultra-precision needs

Industry Applications of 4-Axis & 5-Axis CNC Machining Services

According to statistics, enterprises adopting multi-axis precision machining solutions have reduced repetitive fixture setups by 70% on average and shortened production cycles for complex components by over 35%. Among the global TOP 10 medical device suppliers, 9 have integrated 5-axis machining into their core processes. In the aerospace sector, multi-axis systems help manufacturers avoid more than 26,000 part scrappages annually due to precision-related defects. Similar 4-axis and 5-axis machining technologies are widely applied across industries, such as:

Automotive Manufacturing

Applications:

High-pressure fuel injector nozzles, aluminum EV battery trays with integrated cooling channels, and turbocharger turbine housings.

Examples of technical challenges:

- ±0.005mm fuel injector channel tolerances

- 40% faster EV battery tray milling via 4-axis vibration-dampened toolpaths

Medical Devices

Applications:

Porous titanium spinal cages, cobalt-chromium knee joint femoral components, and endoscopic tool shafts.

Examples of technical challenges:

- 0.03mm porous spinal implants with 5-axis micro-milling

- Biocompatible mirror finishes (<0.1μm Ra) using 4-axis C-axis grinding

Industrial Projects

Applications:

Multi-cavity injection molds, die-casting inserts for automotive lighting, and stamping die assemblies.

Examples of technical challenges:

- 15° tool angles eliminate EDM, cutting mold lead time by 40%

- 0.005mm lens curvature consistency across 500+ cycles with 4-axis polishing

4 axis and 5 axis CNC machined Part Gallery

Both four-axis CNC machining and five-axis CNC machining are types of multi-axis CNC machining. Typically, both processes can complete the machining of most shapes.”

How to start a project with 4-axis and 5-axis services

Machining Tolerance Standard

This table outlines First Mold’s recommended tolerance standards. If you do not have specific tolerance requirements for your product, we will proceed with machining based on the standard class. Additionally, our colleagues will contact you promptly to analyze and recommend tolerances for your product based on our experience.

| Tolerance Type | Tolerance Range | Application | Description |

| Dimensional Tolerance | ±0.005 mm (±0.0002″) to ±0.1 mm (±0.0039″) | General parts with standard precision | Standard dimensional tolerances, suitable for most general machining tasks. |

| Geometric Tolerance | ±0.01 mm (±0.0004″) to ±0.05 mm (±0.002″) | Complex parts needing precise geometry | Controls the form, orientation, location, and runout of features. |

| Straightness | 0.005 mm (0.0002″) to 0.02 mm (0.0008″) | Components requiring straight edges | Ensures that a surface or axis is perfectly straight. |

| Flatness | 0.005 mm (0.0002″) to 0.03 mm (0.0012″) | Parts needing a flat surface | Ensures the part’s surface does not deviate from the ideal flat plane. |

| Cylindricity | 0.01 mm (0.0004″) to 0.05 mm (0.002″) | Cylindrical parts with strict tolerances | Controls the roundness and straightness of cylindrical surfaces. |

| Concentricity | 0.01 mm (0.0004″) to 0.03 mm (0.0012″) | Parts where concentricity is crucial | Ensures that features (e.g., holes, shafts) are aligned within a common centerline. |

| Perpendicularity | 0.01 mm (0.0004″) to 0.05 mm (0.002″) | Parts needing precise perpendicular surfaces | Ensures that features are exactly perpendicular to each other. |

4-Axis & 5 Axis Machining FAQ

What materials can your 5-axis machines handle for high-temperature applications?

Our 5-axis heat-resistant machining processes Inconel 718 (HRC 45), titanium Ti-6Al-4V, and PEEK composites, achieving:

- 200°C+ cutting stability with liquid-cooled spindles

- 0.02mm flatness on ceramic turbine shrouds after 8-hour continuous runs

Is 5-axis machining cost-effective for small batches under 50 pieces?

Yes! Multi-axis prototyping cuts costs by:

No fixture investments – 100+ part variations machined with standard vises

30% lower per-unit cost vs. 3-axis after 20+ units (via reduced setups)

How do you prevent tool deflection in deep 4-axis cavity machining?

Our 4-axis rigidity control protocol combines:

AI-powered feed rate adjustment based on real-time vibration sensors

Modular tool extensions (L/D ratio up to 12:1) for mold cores >150mm deep

Can you machine optical-grade surfaces without polishing?

With 5-axis diamond turning, we deliver:

Ra 0.02μm mirror finishes on aluminum reflector molds

<0.1 arc-minute angular accuracy for laser collimator housings

Do your 4-axis services support Swiss-type lathe parts?

We optimize 4-axis mill-turn for complex shafts/connectors:

0.005mm concentricity on hypodermic needle hubs

Thread rolling + knurling in single setup for hydraulic fittings

Can you match our internal coating specs after CNC machining?

Post-processing options include:

Anodizing (MIL-A-8625 Type III)

Electroless nickel plating (ASTM B733 Class 4)

PVD coating for molds (AlCrN up to 3200HV)