Anodizing

- Home

- Surface Finishing

- Anodizing

What's Anodizing?

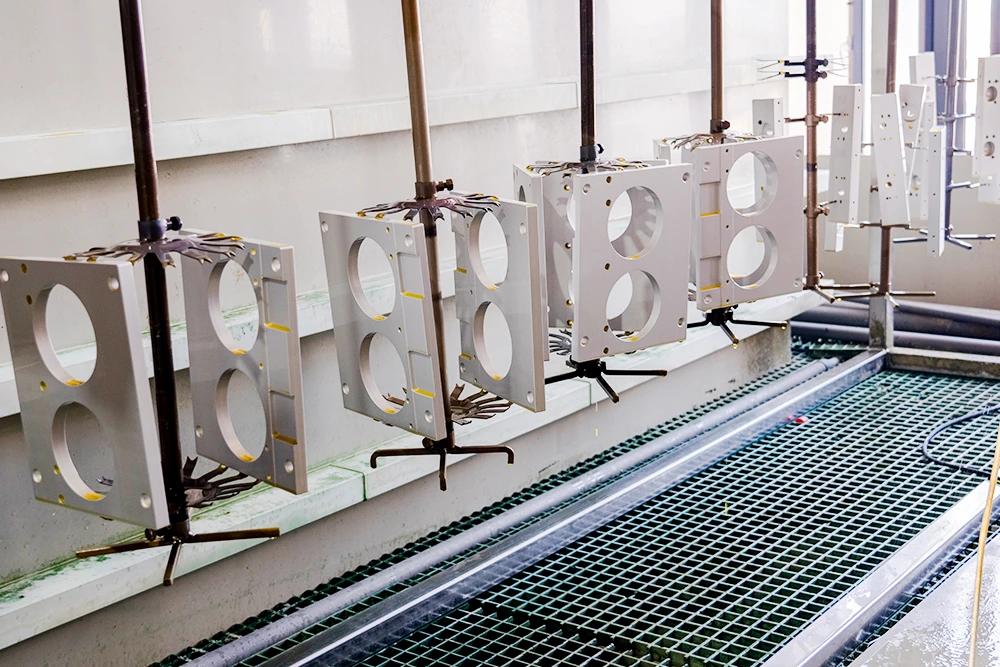

The anodizing process is a metal surface treatment technology most commonly used for aluminum and aluminum alloys. The main principle of this process involves placing the metal product as the anode in a specific electrolyte solution. Through electrolysis, an oxide film is formed on the surface of the product, thereby imparting protective and aesthetic characteristics.

The anodizing process at FirstMold comes from our stable suppliers with whom we’ve partnered for over a decade. They are efficient, high-quality, and affordable, capable of meeting your metal parts’ appearance requirements.

Anodizing Finish Appearance Showcase

Optical Lens

Bicycle Hubs

Automotive Parts

Medical Components

Decorative Parts

Grinders

7000 Series Aluminum

Flashlights

The colored anodizing process makes it possible to choose from a variety of colors.

Black

Gray

Red

Orange

Yellow

Green

Blue

Purple

Advantages of Anodizing for Your Product

Improve Corrosion Resistance

It forms a protective aluminum oxide film that prevents further oxidation

Improve Wear Resistance

It enhances wear resistance by creating a hard oxide film that reduces scratches and wear.

Improve Insulation

It can provide electrical insulation with a non-conductive oxide film for applications requiring insulation.

Anodizing Options

| Anodizing Types | Price | Available Colors |

|---|---|---|

| Bright Anodizing | $$$ | Clear, Black, Gold, Blue, Red |

| Chromic Acid Anodizing | $$ | Clear, Light Gray |

| Colored Anodizing | $$ | Custom Colors (Red, Blue, Green, Gold, etc.) |

| Electrolytic Coloring | $$ | Bronze, Black, Gold |

| Hardcoat Anodizing | $$$ | Clear, Black, Gray |

| Integral Color Anodizing | $$$ | Black, Bronze, Brown |

| Sulfuric Acid Anodizing | $$ | Clear, Black, Red, Blue, Green, Gold |