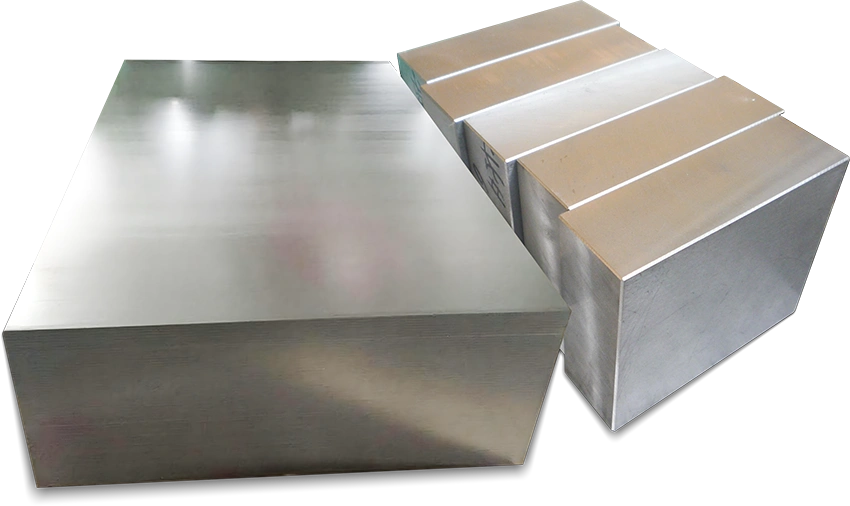

Mold Making Materials

Mold manufacturing involves a variety of sub-materials, such as mold steel, special alloys, and so on. The choice of materials is crucial for the quality of the mold. High- quality mold making materials can ensure that the mold maintains accuracy and stability over a long period. They also determine the performance of injection molding production, helping to produce good plastic products.

Brief understanding of mold making materials

For our customers, a basic understanding of mold-making materials can also provide a small help for their own products.

This knowledge facilitates clearer communication and more accurate specifications, enabling our customers to make informed decisions about materials based on their product’s performance, cost, and quality. It helps our customers set realistic expectations for product performance and limitations, understand the general costs of product manufacturing, and plan for potential supply chain issues.

| Material Type | Common Grades | Characteristics | Typical Applications |

|---|---|---|---|

| Stainless Steel | 420 | Corrosion-resistant, hardenable | Medical or food-grade molds |

| 6061 | Good combination of strength, weldability | Non-critical parts, mold bases | |

| Carbon Steel | 1018 | Good machinability, low cost | Prototype molds |

| Zinc Alloys | ZA-12 | Good strength, lower cost than aluminum | Die casting molds |

| Pre-Hardened Steel | 4140 | Good toughness, high fatigue strength | Gear, automotive molds |

| Chromium Steel | 52100 | High hardness, wear resistance | High-precision bearings, molds |

| High-Speed Steel | M2 | High heat resistance, wear resistance | High precision molds, cutting tools |

| 17-4PH | High strength, good corrosion resistance | Aerospace, automotive molds | |

| Aluminum | 7075 | High strength, lightweight | Prototype, low-volume molds |

| Beryllium Copper | Alloy 25 | High thermal conductivity, strength | Cooling inserts, hot runner systems |

| 4340 | High toughness, high strength | Large molds requiring toughness | |

| D2 | High wear resistance | Stamping molds | |

| 1045 | Higher strength, medium carbon steel | Low-volume production molds | |

| H13 | Hot work steel, high toughness | High-volume injection molds | |

| Tool Steel | P20 | Pre-hardened, good polishability | General-purpose molds |

| S7 | Shock-resistant | Molds requiring high impact resistance |