Home / Manufacturing Services / Injection Molding Service / Family Molding Service

Family Molding Service | Production of Multiple Parts by One Mold

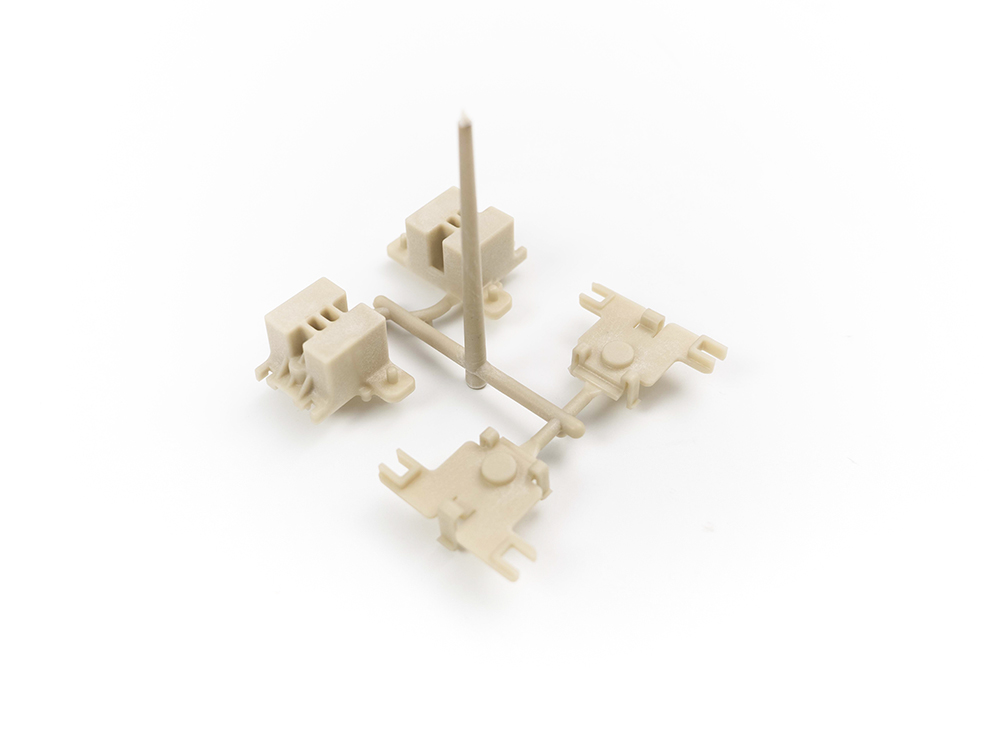

Family molding, where different parts are produced simultaneously with one set of molds.

What is family molding?

Family Molding Services from the Best Suppliers

This is a common one-stop solution for multi-component injection molding needs, which can help you reduce costs and ensure precision.

High-precision Molding

Advanced mold design and precise process control ensure the dimensional accuracy of each part, reaching the industry-leading standards.

Efficient Production

Family Molding reduces the running times of injection molding machines and the frequency of mold replacement, significantly improving production efficiency and saving time and costs.

The technological advantages of family mold help to boost orders

Mold Design

Mold designers are proficient in unique algorithms for optimizing the layout of cavities. This ensures that the plastic melt fills each cavity evenly and avoids defects like short shots and flash.

Process Control

With a reasonable department structure and good collaboration, we make use of advanced equipment control systems to monitor and accurately adjust parameters like temperature, pressure and speed in real time.

Quality Inspection

From the inspection of raw materials to the random inspection of finished products, we use a variety of professional testing equipment, such as high-precision coordinate measuring machines and material property testers.

Design Concept and Precision Machining of Family Mold

In the Family Molding process, the family mold is as crucial as the cornerstone. Its quality and precision are directly related to the success or failure of the entire injection molding process. A high-quality family mold is the core element to ensure the efficient and precise operation of Family Molding.

Design Concept of Family Mold

Multi-cavity Adaptive Layout: According to the matching requirements of products, the cavities of parts with different shapes and sizes are skillfully arranged.

Optimized Runner Design: The runner is planned based on the characteristics of plastic materials. For plastics with weak fluidity, the main runner is widened; and the gate is selected according to the shrinkage rate. For example, a pinpoint gate is used for high-precision plastic parts to ensure molding accuracy.

Precision Machining of Family Mold

Ensuring Accuracy through CNC Precision Milling: High-precision CNC milling is adopted, and complex cavities are processed with five-axis linkage to create a smooth surface with micron-level accuracy

Enhancing Performance through Strengthening Treatments: Heat treatments such as quenching and tempering are carried out to adjust the hardness and toughness according to the force on the mold;

Family Mold Making & Family Molding Cases