Home / Industries / Medical

Medical Device Components & Parts Manufacturing

The Premier Factory for Manufacturing and Processing Metal and Plastic Medical Device Parts

- Diverse styles, customization supported

- Careful selection of raw materials, exquisite workmanship

- Comprehensive and varied manufacturing and processing methods

- Timely delivery, superior packaging support

Firstmold has worked with startups and big-name players to explore innovation and intuitive digital manufacturing solutions that have shaped the supply chain agility and response in the medical industry. From fitness trackers, to health monitors, wearables, prosthetics and more, our medical manufacturing services are the ideal for flexibly building prototypes and ramping up production at convenience.

Safety, Precision and Quality First

Experiences in Medical Components:

FirstMold’s engagement in the medical and healthcare industry’s device making dates back to 2012. The company’s leadership recognized that supporting global health aligns with the company’s philosophy, and it was essential to contribute our efforts to the medical and healthcare field.

For over a decade, FirstMold has leveraged its multi-domain part manufacturing and processing strengths to diligently produce each medical device part. We primarily complete each client-assigned project through CNC machining, injection molding, and 3D printing, earning unanimous praise from customers worldwide.

- Instant Quoting and DFM feedback

- Steel Tooling with samples in 7 days

- High Precision, Tight tolerance Parts

“With the help of our partner, FirstMold, we are able to deliver products that match our medical standards and requirements for complex parts. This is the reason why their expertise in CNC machining is integral to the process of developing our medical devices.”

Sarah Nguyen

Lead Design Engineer

“The choice of using FirstMold’s injection molding services at our end has made our company be able to earn fame as one of the leading producers of medical parts, which are as durable and reliable as our customers in the health sector need. The added expertise in medical grade materials by FirstMold is an assurance that all the parts that come out are top quality.”

Alex Rodriguez

Supply Chain Coordinator

In our medical device prototyping, FirstMold’s 3D printing capabilities have proven to be very valuable as it offers a shortened lead time and complies with high precision. Through FirstMold’s quality-driven attitude, the success in our effort to produce cutting-edge medical solutions has been achieved.

Michael Johnson

Operations Manager

Medical Gallery

- Instrument Housings

- Functional Components

- Connectivity and Interface Parts

- MRI Machines

- Ultrasound Devices

- Blood Pressure Monitors

- Surgical Robots

- Centrifuges

- Ventilators

- Glucose Monitors

- Defibrillators

- Sterilization Equipment

- Dialysis Machines

- Laboratory Analyzers

- Telehealth Devices

- EMR Systems

- Insulin Pens

- Digital Thermometers

- Hearing Aids

- Pulse Oximeters

- Smart Inhalers

- Portable ECG Monitors

- Portable X-ray Machines

- Dental Drills

- Curing Lights

- Intraoral Cameras

- Impression Systems

- Biomicroscopes

- Visual Field Testers

- Ventilators

- Nebulizers

Notes: Due to the NDA signed with our clients on most projects, we are only able to select and display the appearances of a few products from the medical industry after obtaining consent through communication with our clients.

Diagnostic and Monitoring Device Parts

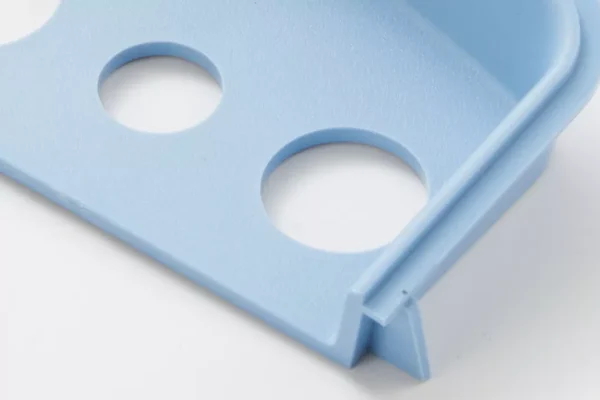

Diagnostic Device Housing

| Process: | Mold Making, Injection Molding |

| Materials: | ABS |

| Solutions: | Mass Production |

| Tolerance: | ±0.005" |

Medical lighting tool housings

| Process: | Mold Making, Injection Molding |

| Materials: | PC+ABS |

| Solutions: | Mass Production |

| Tolerance: | ±0.005" |

Support and Mobility Device Parts

Hearing aids

| Process: | Production Tooling, Injection Molding |

| Materials: | PC+ABS |

| Solutions: | Mass Production |

| Tolerance: | ±0.005" |

Rehabilitation chair components

| Process: | CNC Machining |

| Materials: | Zinc Alloy |

| Solutions: | Mass Production |

| Tolerance: | ±0.002" |

Aerospace Manufactuing Solutions For Recommended

Medical CNC Machining Services

Particularly suitable for customers requiring high-precision, custom, or complex parts with tight tolerances for critical medical devices and equipment.

- Precision and Accuracy

- High-Quality Surface Finishes

- Scalability

- Compliance with Medical Standards

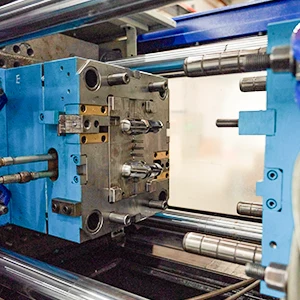

Medical Injection Molding Services

Ideal for customers needing large volumes of plastic parts with consistent quality, such as disposable medical devices, housings for medical equipment, and components for diagnostic devices.

- High Volume Production

- Speed to Market

- Complex Part Design

- Consistency and Reliability

Trusted by various famous Medical brands over the world

- Medical component manufacturers

- Diagnostic equipment suppliers

- Pharmaceutical companies

- Biotech Companies

- Hospital Operators

- Surgical Experts and Medical Product developers

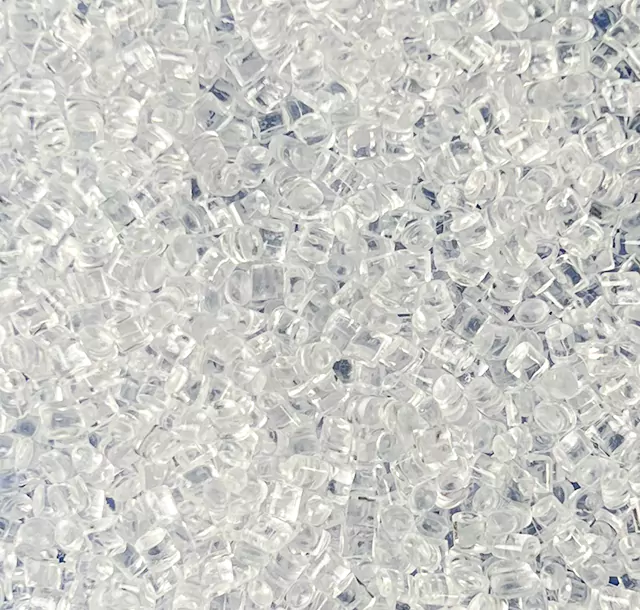

Medical-grade Material Options

The medical device and healthcare industry is distinct from other sectors: many products are directly applied to the human body, hence we strictly adhere to industry standards in our use of materials, especially for plastic material parts. Although this approach leads to a certain amount of raw material waste, we consistently refuse to use recycled materials for injection molding production, and this standard is upheld in the manufacturing of parts for other industries as well.

We can provide raw material certification for all processing methods and can also purchase from suppliers specified by clients. Our expertise includes the following raw materials:

| Materials | Typical Applications |

|---|---|

| Titanium | Ideal and bio-compatible for skeletal and internal joint orthopedic applications, Titanium has great strength-to-weight ratio and is corrosion-resistant. It can also be 3D printed or machined to meet tight tolerances |

| Stainless Steel & Inconel | Medical grade stainless steel is easy to sterilize, heat resistant and excellent for making precision surgical instruments. These materials are also corrosion resistant and can be used as implants for bone replacement. |

| Nylon & ABS | Nylon and ABS are ideal for making medical appliances and other medical instruments. They are 3D-printable and are excellent for rapid prototyping or on-demand use parts. |

| Silicone and TPE | Silicone and TPE are ideal for custom parts that will have high interaction against the surface of the skin. These materials are excellent for handhelds and wearables and have chemical resistance. |

| POM, PEI and PEEK | POM, PEI and PEEK are engineering-grade plastics that have high strength and durability. They can be used in orthopedic applications for support around joints. These materials are sterilizable with high fatigue and creep resistance. |

Medical Components Surface Treatment

Many medical device parts are considered appearance parts, and clients often have high aesthetic requirements. We possess a complete supply chain for part surface treatments, ranging from simple silk screening to complex electroplating, most of which are carried out in our own factory.

For instruments parts without any specific requests, we typically apply high-gloss finishing or adhere to industry standards. When you receive the finished product, you will undoubtedly be surprised by our exquisite craftsmanship.

Factory Gallery

These images will give you a better understanding of FirstMold, enabling you to make the most informed decision when choosing a supplier for manufacturing medical device parts.