Home / Manufacturing Services / Injection Molding Service / Insert Molding Service

Insert Molding Service | Cut Down on Assembly Processes

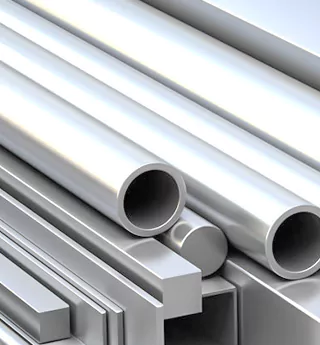

The aesthetic combination of metal and plastic with insert molding

- Experienced team provides reliable and efficient service

- Competitive pricing for various insert molding projects

- Wide range of materials and insert options

Achieve Stronger, More Efficient Parts with Insert Molding

Firstmold’s insert molding process is a versatile and efficient solution for creating complex parts with greater strength and durability. By combining multiple materials or components into a single molded part, insert molding can significantly reduce assembly time and costs while also improving part performance.

Our state-of-the-art machinery and experienced technicians allow us to precisely mold inserts into parts, achieving greater reliability and consistency. From prototyping to high-volume production, Firstmold’s insert molding capabilities offer a reliable and cost-effective solution for your custom part needs.

- Screws Inserts

- Contacts Inserts

- Studs Inserts

- Pins Inserts

- Clips Inserts

What you can make with insert injection molding?

Insert molding is a versatile manufacturing process that enables the production of complex and high-precision parts. At Firstmold, we have extensive experience in insert molding and have successfully produced a wide range of parts and products for various industries. For example, we have produced microelectronic components such as connectors, switches, and sensors that require high precision and tight tolerances. Additionally, we have manufactured automotive parts such as gears, housings, and brackets that require high strength and durability.

Material Selection For Insert Molded Parts

Choose the main material for your injection molding product

We are well-versed in hundreds of plastics or other materials for injection molding, including single materials, mixed materials, modified materials, rubbers, etc. We are familiar with their physical properties, chemical properties, and all parameters.

Also, because of the strength of our supply chain system, we can obtain these raw materials in a timely and stable manner without any impact on your product delivery.

Dare to imagine, dare to insert

Insert injection molding is generally most commonly used for the insertion of screws or studs, brass will not rust and has characteristics of corrosion resistance. It is affordable and easy to process. which makes it the most commonly used material in insert molding.

In addition, copper, aluminum, steel, hard dissimilar plastic parts, ceramics, glass, and plastic can be used as insert materials. In the product application, we will design the shape and structure of plastic parts according to the thermal expansion coefficient of different materials.