Global Custom Parts Manufacturing On-Demand

Upload your 3D model to activate multiple manufacturing processes for part production. Complex parts, rapid prototypes, medium batches, and large-scale production are available. Access an extensive material library, precision surface finishing, DFM, product assembly, and global door-to-door delivery services.

2025®快速5分钟|澳洲幸运5查询走势图-澳洲体彩幸运五(中国)官方网站-澳洲幸运5网站168

As your digital manufacturing partner, First Mold delivers end-to-end production solutions through a unified online platform. With our one-stop shop services in both subtractive and additive manufacturing, we eliminate the need to coordinate with multiple suppliers. Upload your design once to manage prototyping, custom part production, and scalable volume manufacturing in a single workflow.

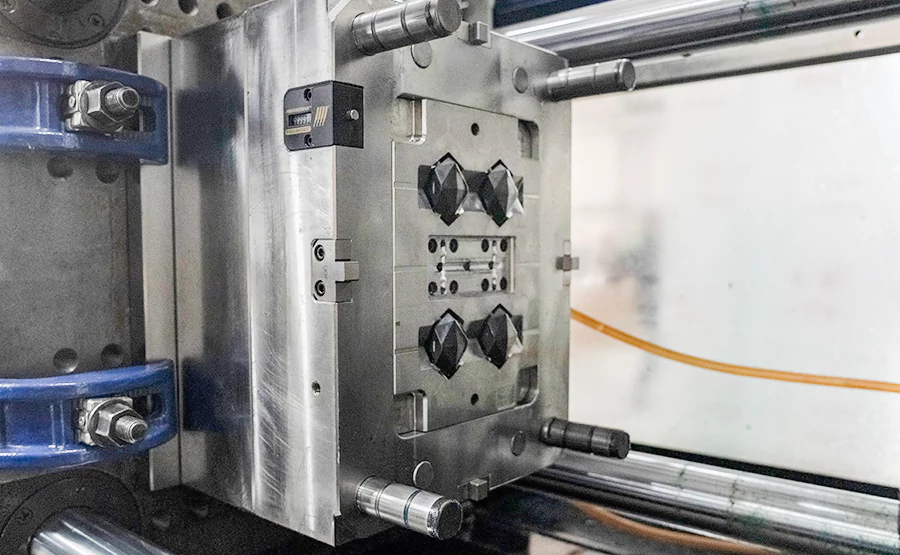

Steel/Aluminum injection molds, die casting molds, and stamping tools. Accelerate your production with 30% faster tooling delivery and certified mold lifecycle management.

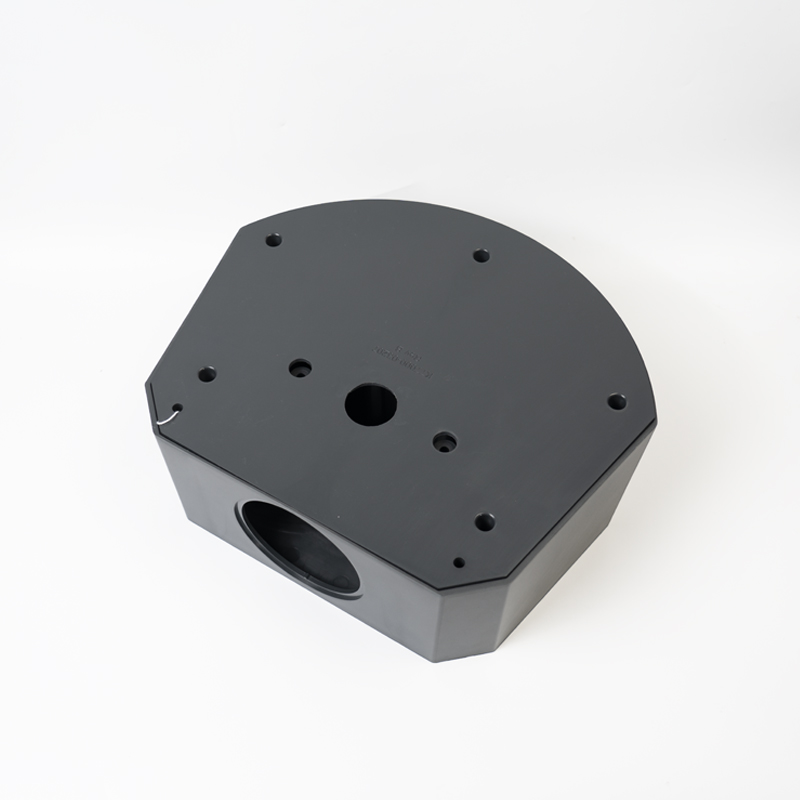

From custom plastic parts prototyping to high-volume production, we deliver precision injection molding with 500+ engineering-grade thermoplastics and ±0.01mm tolerance.

Precision CNC machining of metal alloys & engineering plastics. Optimized for complex part geometries, tight-tolerance (±0.005mm) components, and low-to-high volume production.

On-demand 3D printing services via SLA, SLS, FDM technologies. Produce functional prototypes and end-use parts in 48 hours with 20+ industrial polymers.

See How We Transform Ideas into Precision Parts

From low volume manufacturing to mass production, First Mold has delivered 10000+ mission-critical parts for global industries.

We never stop exploring the path of plastic parts and metal parts. Cases are the proof of strength of a good company.

Mass Production of Small Button Parts

Injection Molding of VR Headset Front Cover

Silicone Injection Molded Baby Mask

Inspection Equipment Housing Manufacturing By Insert Molding

Production Of Automotive Armrest Bases Through The Injection Molding

Custom Plastic Molding For VR Remotes Controller Housing Manufacturing

2025®快速5分钟| 五福彩-官方澳洲幸运5开奖结果体彩网

The skilled application of our processes supports us in completing different types of parts manufacturing and production projects. As a reliable custom parts manufacturer, we have delivered over 20,000+ custom parts to global customers via our online manufacturing services. We believe there must be projects among them that are the same as or similar to your industry and products. We can transform all your drawing requirements into mass-producible industrial-grade products.

- Battery Case

- Interior Panel

- Light Lens

- Sensor Bracket

- Engine Block

- Brake Caliper

- Control Knob

- Charging Port

- Phone Case

- Earphone Body

- Button Film

- Antenna Mount

- Camera Ring

- SIM Tray

- Hinge Assembly

- Heat Sink

- Syringe Tube

- Valve Body

- Catheter Tip

- Surgical Grip

- Guide Plate

- Dental Implant

- Device Shell

- Face Mask

- Robot Cover

- Drill Bit

- Hydraulic Valve

- Milling Cutter

- Gripper Jaw

- Sensor Mount

- Bearing Race

- Tool Fixture

- Fuel Nozzle

- Heat Shield

- Seat Frame

- Galley Panel

- Headrest

- Tray Table

- Buckle Cover

- Ceiling Trim

- Razor Handle

- Shower Head

- Lipstick Case

- Hairdryer

- Massager Shell

- Skin Scanner

- Acne Tool

- Epilator Blade

First Mold has worked on far more parts production projects than these. Upload your drawings, and our staff will contact you as soon as possible. You can confirm with our staff whether we have prior experience in your project.

What Kind of Parts Manufacturing Company is First Mold?

First Mold is a custom parts provider with three major manufacturing bases (two in China, one in Mexico). Over more than a decade of development, First Mold has also gradually become one of the top ten online parts-making services platforms, with significant influence in North America, Europe, and the Asia-Pacific region.

Leveraging a wide range of processes, First Mold has established mature project management models for both plastic parts and metal parts, continuously providing precision custom parts manufacturing services to over 30 countries, including the USA, Canada, Mexico, the UK, Germany, France, Sweden, Italy, Spain, Australia, Belgium, Japan, South Korea, and mainland China.

- Bases in China and Mexico, global services are available, tarriff issues solved

- 30,000㎡ factory

- Comprehensive employee structure

- Business global expansion map

Why Choose Us to Make Custom Parts

Served Countries

Technical Personnel

Advanced Equipments

Process Types

For engineers and procurement teams, selecting a custom parts manufacturer goes beyond ticking boxes for ISO certs or machining capabilities. It’s about partnering with experts who convert compliance into real-world ROI:

- How swiftly can they resolve tolerance stack-ups without delaying production?

- Will tariffs eat up the cost savings?

- Can they transition from low-volume prototypes to high-volume production without chaos?

Here’s why global innovators choose us as their long-term supplier:

Dual Manufacturing Hubs

Facility In Mexico - North America & Europe Market

Our Guanajuato-based Mexico factory is engineered for nearshore manufacturing excellence. Strategically positioned near Texas border crossings and Atlantic freight routes, we guarantee:

- North America: Detroit, Los Angeles, Houston, Chicago, Philadelphia, Cleveland, Pittsburgh, Seattle, Atlanta, Dallas, Austin, Phoenix, Toronto, Montreal, Windsor, Edmonton

- Europe: Munich, Stuttgart, Birmingham, Turin, Barcelona, Eindhoven

- Tariffs: USMCA/CUSMA compliance for CNC, molded, and stamped parts

- Bilingual Engineering: Spanish/English DFM reviews within 6 hours

Facility In China - Asia-Pacific Market

With two advanced facilities in Zhongshan, our Chinese bases serve as the backbone of high-efficiency manufacturing for industrial hubs across Asia and Europe. Located within 50km of raw material clusters and major ports, we deliver:

- Key Service Cities: Osaka, Seoul, Chennai, Rotterdam, Hamburg, Warsaw

- Rapid Response: 72-hour mold trials for design validation

- Flexible Production: Seamless scaling from 50-unit prototypes to 500,000-unit batches

Precision-Built Teams, Precision-Made Parts

Behind every precision part is an ecosystem of specialized teams, not just machines. First Mold’s departments are hardwired to eliminate your supply chain risks:

- No handoff gaps: Mold engineers are the central link between the CNC shop and molding shop..

- No accountability voids: Your project manager owns the entire workflow.

- No compatibility guesswork: Design, tooling, and QC use the same digital thread.

| Department | Tags |

| Injection Molding Workshop | 1. 90-1600T Clamping Force 2. 500+ Material Profiles Pre-Loaded |

| Mold Fabrication Workshop | 1. ±0.0254mm(±0.001″) Cavity Precision 2. 72hr Rapid Tooling Trials |

| CNC Machining Workshop | 1. 5-Axis Simultaneous Machining 2. 50+ Haas & GF+ Machines |

| Quality Inspection Department | 1. CMM Scanning: 0.001mm Accuracy 2. 100% Batch Traceability |

| PMC Department | 1. Real-Time Production Dashboards 2. 48hr Engineering Change Implementation |

Injection Molding Workshop

Mold Fabrication Workshop

Mold Machining Workshop

CNC Machining Workshop

Quality Inspection Department

4 Parts Manufacturing Solutions

Applying industrial-grade 3D printing, 5-axis CNC machining, and rapid injection molding, we transform CAD files into functional prototypes within 72 hours. Unified mold flow analysis ensures your design is production-ready from the first sample.

Combining rapid tooling, precision die casting, and CNC machining, we deliver 50-5,000 bridge production units in 15 days. Flawlessly switch between engineering plastics and metal alloys while maintaining tight tolerances.

High-Volume Parts Manufacturing

Powered by automated injection molding lines and production-grade molds, we guarantee 40,000+ daily outputs. Our China-Mexico dual hubs optimize costs and speed for million-unit orders with zero supply chain disruptions.

Contract Manufacturing Services

End-to-end custom manufacturing solutions integrating additive manufacturing and subtractive manufacturing. From raw material sourcing to global logistics – we handle it all, freeing you to focus on product innovation.

Precision Metal & Plastic Parts Manufacturing

The engineers at First Mold master the majority of materials used in component manufacturing.

Metallic materials are primarily applied in our mold manufacturing, CNC machining, 3D printing, and die-casting processes. Common metal processing materials include aluminum alloys, zinc alloys, stainless steel, various tool steels, and copper.

Plastic materials are mainly used in injection molding, CNC machining, and 3D printing processes. Common plastic processing materials include ABS, PC, PA66 (Nylon 66), POM, PP, PE, PMMA, PPS, PEEK, LCP, PET, PBT, PS, and PVC.

See what our customers said

“When we first requested CNC machining, we tried to contact First Mold. They responded within hours with prices, delivery times and suggestions for our requirements. I am really satisfied with their professional service and high quality control. I would recommend them to my friends Without hesitation.”

“We have been cooperated with Firstmold in injection molding for 6 years. From design to production, First Mold provides excellent and professional injection molding services as well as the high quality products. We feel they are one of the best plastic parts manufacturers We've met in China.”

“First Mold is our the most satisfactory die supplier. They are high efficiency and high quality control. Since 2016, we have cooperated with them on many projects, they also provided professional product suggestions to help us complete the projects. That’s why they’re such a great injection mold company.”

How to Manufacture with First Mold?

1. 3D Design Upload

Submit 3D CAD models and discuss technical specifications with engineering teams.

2. DFM Analysis & Quotation

Conduct Design for Manufacturability (DFM) verification and provide cost estimation

3. Component Making Process

Execute advanced manufacturing methods including CNC precision machining, injection molding, 3d printing, etc.

4. Quality Inspection & Delivery

Implement dimensional accuracy checks and arrange certified logistics for high-grade components.

Human quotation is the primary pricing method on our manufacturing platform. After uploading your part’s 3D file, our project managers will contact you within 2 hours. Based on your uploaded manufacturing requirements, we will provide the most accurate quotation.

The quotation generation system is powered by First Mold’s self-developed AI quotation system. After you upload 3D drawings, material specifications, quantity, surface treatment requirements, and other needs, the system will instantly provide an approximate quotation for your reference.

Why Go Online? Precision Manufacturing Simplified

Digital manufacturing isn’t just convenience – it’s a competitive edge. By utilizing our online part fabrication platform, you unlock:

- Zero Guesswork: AI-powered instant quotes backed by human expertise.

- Speed to Market: 70% faster approvals vs. traditional RFQ processes.

- Global Consistency: Same platform, same quality – whether parts ship from Mexico or China.

- Cost Control: Transparent pricing with no hidden fees (mold costs amortized automatically).

Latest News & Article

Compare TPU and TPE in engineering: durability, lightweighting, NVH, and smart materials. Learn selection criteria for automotive, aerospace, and medical applications.

Explore gas-assisted injection molding (GAIM) techniques, advantages over standard methods, material savings, lightweight applications.

Learn how to make plastic prototypes from start to finish: set goals, design in CAD, select materials and prototyping methods, then test, iterate and cut costs.

Create durable metal prototypes faster: Step-by-step guide with industry cases (aerospace/medical), cost-saving tips, and compliance testing methods.